Basic kiln hoods – successful and innovative refractory concepts

The kiln hood of a rotary kiln in a cement plant connects the hot area of the kiln with the clinker cooler and is therefore always exposed to high thermal and process-related stresses. In recent decades, these loads have steadily increased in consequence of the use of alternative fuels and thereby induced higher process temperatures. For system builders, this means an enormous design effort, when rotary kilns are modernized.

1 Introduction

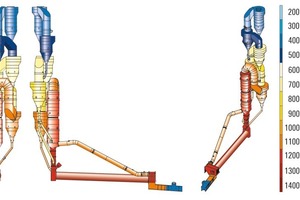

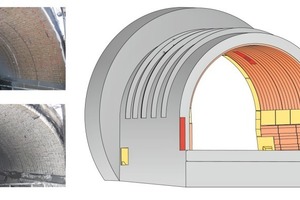

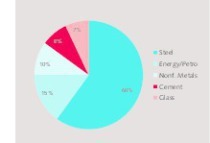

As a static unit, the kiln hood of a cement plant connects the hot area of the rotary kiln with the clinker cooler, and is therefore subjected to correspondingly high loads. In the past decades, these loads have increased continuously as a direct result of developments toward cement plants with modern process conditions, the use of alternative fuels as well as higher process temperatures (Fig. 1).

Especially the increasing modernization of older rotary kilns, that means the change from satellite coolers to more efficient grate coolers and correspondingly dimensioned kiln hoods,...