Woven wire cloth and woven wire products

Haver & Boecker OHG comprises the Wire Weaving and Machinery Divisions. The Haver & Boecker Machinery Division will be exhibiting under the motto “Perfect Flow for our blue planet”. The Wire Weaving Division manufactures woven wire cloth and processes it into engineered woven wire products.

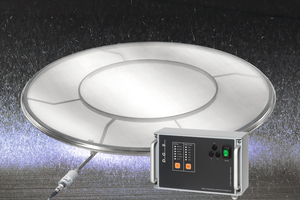

Ultrasonic screens in all variations

For years Haver & Boecker have been collaborating with Artech Ultrasonic Systems AG to provide custom-made ultrasonic screening systems with innovative frequency variation. Ultrasonic screening solutions by Haver & Boecker can be used for cut sizes of approx. 1000 µm to 25 µm. Existing screening units with pre-tensioned screen frames can be retrofitted with this innovative technology.

The system comprises all required components from the pre-tensioned screen frame with waveguide-system over the ultrasonic converter and the generator to the support elements, if needed. With their “Plug’n’Sieve” concept, ultrasonic screen frames with Artech frequency variation offer great user convenience: Simply install the screen frame, connect the Artech components, and immediately start screening with higher throughput.

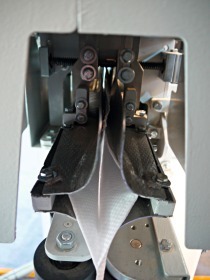

New generation of dynamic image analysis (DIA)

The proven Haver CPA 2-1 laboratory device for the photo-optical analysis of particle size and shape of dry, non-agglomerated loose particles has been revamped to include new technological developments.

The measurement range has been expanded and extends from 0.020 to 30 mm. Moreover, because of the improved measurement quality, analyses are now more precise and comprehensive.

An important and decisive detail for optimizing the work process and measurement quality of the Haver CPA 2-1 analysis device is also the continuously developed software. The latest Windows and operating standards with full support for Windows 10 go without saying. Furthermore, offered are many new characteristic value options and optimized features such as automatic hopper heights, ultrasound and pre-drying.

Evaluation software from Haver & Boecker

With help of the Data Matrix Code (DMC) and the scanner sieve details can automatically be imported into the sieve file of the Haver CSA (Computerized Sieve Analysis) software. The scanning function enables to create and choose a sieve set. With help of the scanning function you also check if the correct sieves are in the right order for the sieving process.

Two packages are available: 1. Full Version Haver CSA Expert with Scanner, and 2. Haver CSA upgrade to Expert with manual scanner.

The Data Matrix Code may be laser-etched onto existing test sieves that have stainless steel frames.

The advantages of the Haver CSA with sieve recognition:

• Efficient capturing of screen data

• Simplified weighing of the test sieves

• Definite mapping of the test sieves

• Confirming correct sieve order

• User-friendly and intuitive user interface