Packaging as a key factor for success

The Haver & Boecker Machinery Division will be exhibiting under the motto "Perfect flow for our blue planet". Here the focus is on sustainability and conserving resources. The packaging specialist from Oelde/Germany is presenting itself along with the Haver & Boecker Wire Weaving Division and the mineral processing experts from Haver & Boecker Niagara.

The Wire Weaving Division will be presenting new and proven products from its range for particle analysis, screening and filtration. Among the innovations for the laboratory sector are also the Haver CSA evaluation software with sieve recognition function and other accessories.

Haver & Boecker Niagara develops, builds, delivers and supports complete plants as well as special machines and plant components for mineral processing technology. The eccentric technology has been consistently developed in the worldwide subsidiaries since 1930, thus assuring its leading international position. Today the product range includes three different eccentric screening systems which are used depending on the application.

The willingness to sustainably pioneer new methods and use resources responsibly and sparingly will decide what the future holds for our blue planet.

Haver & Boecker is intensively focussed on the question of what role the packaging of bulk goods will play. Which packaging will help us use our resources as sparingly as possible? What impacts does it have on the packaged products? Can the packaging possibly also contribute to reducing the CO2 footprint? The company invites visitors to its stand in order to discuss these topics together.

At bauma the company will be displaying all common packaging types filled by different machine technologies, depending on the customer's requirements, and demonstrating the main advantages of each.

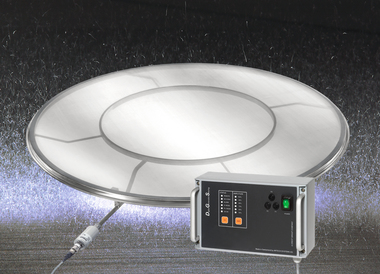

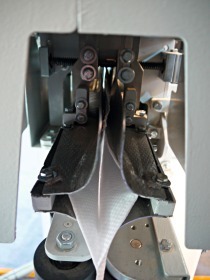

Dust-free work surroundings and a clean bag

Haver & Boecker Machinery Division will focus on the advantages of the Seal technology. At the beginning of this process a sleeve in the specially designed filling spout first inflates and seals the valve bag so that no loose material can escape. After a dust-free filling, the bag valve is ultrasonically welded shut. In addition to cleanliness, safety plays an important role. The ultrasonically sealed, secure packaging protects the environment from possible contamination and promotes safety at all stages of the logistics process. It also protects the filled bulk material from product contamination, removal and product theft.

Cleanliness leads to increased machine availability, reduced operating costs and keeps capacity utilization consistently high. When it comes to sales, the clean and attractive packaging means a significant advantage over the competition.

The Seal technology can be retrofitted to all existing Haver & Boecker packers for valve bags purchased after the year 2000.