Universal classifier head for robust and efficient classification of soft to medium-hard materials

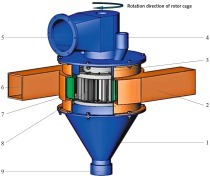

Hosokawa Alpine will present a flexible solution for the ultrafine classification of different soft to medium-hard materials, namely the TTD classifier head. Fineness values to x97 < 3 μm at high throughputs can be achieved. The product line comprises a total of five models, meaning that there is a suitable machine for every requirement. The classifiers are operated either in circuit with ball mills or as stand-alone machines for classification or final classification.

Cost-efficient classification for challenging environments

The TTD classifier head was designed especially for the classification of industrial fillers as well as materials such as limestone, marble or chalk. The machine construction is correspondingly robust. The coarse material classifier is equipped, for example, with an air intake to permit additional product dispersion. Over and above this, the direct

drive has a more powerful motor bearing. The robust classifier head makes not only reliable classification possible, but also operation in a particularly energy- and cost-efficient manner. The reasons: the classifying wheel is supported in bearings on both sides, the two fines discharges as well as the optimised feed product routing direct to the classifying wheel.

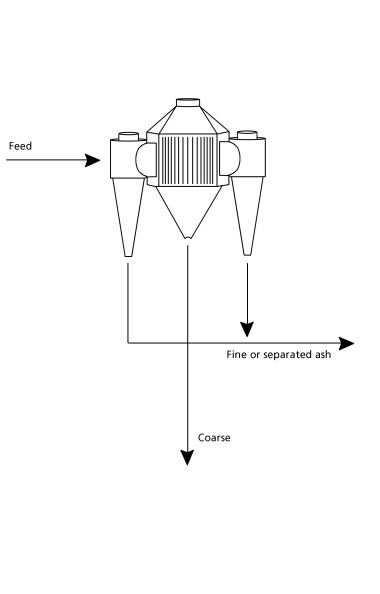

Combination of classifier head and grinding chamber

The flexible design of the TTD classifier head makes it possible to top-mount it on a grinding chamber. This combination results in the TDG jet mill. With this combination, extremely high fineness values are possible which cannot be achieved with conventional jet mills. Mineral powders, for example, can be ground to a fineness of d50 = 0.5 – 1 μm.