Grinding and calcining of gypsum with Pfeiffer grinding plants

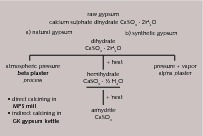

For the production of plaster products natural gypsum, synthetic gypsum or a mixture of both are calcined. Depending on the production process two different modifications of the hemihydrate CaSO4 x ½ H2O are obtained.

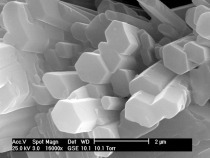

When gypsum is calcined in an atmosphere saturated with water vapour at an overpressure of several bars, a-hemihydrate is formed (Fig. 1). The outstanding feature of this plaster is a relatively regular crystal form. It is created due to the fact that the crystal water is able to escape from the intermediate lattice structure of the CaSO4 slowly and uniformly as escaping is greatly hampered by the counter-pressure built up by the water vapour.

Due to the relatively regular crystal structure and the large individual crystals of the a-hemihydrate, there are few contact surfaces for...