Physical and mechanical properties

of composite cements

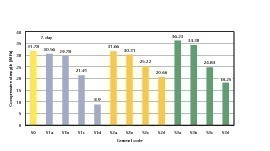

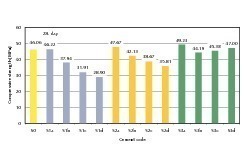

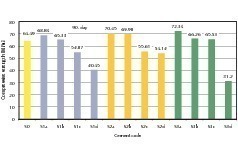

Summary: This paper reports on the results of an experimental study conducted to evaluate the physical properties and strength development of composite cements manufactured with a steel slag (SS) and blast-furnace slag (BFS) combination. The influence of the proportions and fineness of the slag on the compressive strength of the cement blends are presented. Test results showed that the physical properties of the composite Portland cement series were affected by the BFS-SS substitution. The BFS-SS combination used for replacement gave better results when they were ground finer than the Portland cement clinker. The increase in Blaine fineness of the BFS-SS combination had a positive effect on the compressive strength. The substitution ratio can be raised to 60 to 80 % provided the slag fineness value is 4600 cm2/g.

Reuse of some industrial waste materials has become very important during the past decade because of environmental regulations that require waste disposal minimization [1]. Granulated blast-furnace slag (GBFS) and fly ash can be accepted as important materials for this type of utilization [2].

Blast-furnace slag cement has been traditionally produced by intergrinding cement clinker with slag in tube mills or grinding clinker and slag separately [2]. This concept also brought with it the possibility of using various slags with different mix ratios. Basic oxygen furnace (BOF) slag...

![1 XRD pattern of SS after magnetic separation [17]](https://www.zkg.de/imgs/tok_416f0beaad5d90f2f8e7211c8c601ce0/w293_h175_x146_y87_101521483_dd37599967.jpg)