Patented wear

protection for improved

cost efficiency

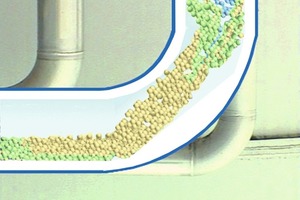

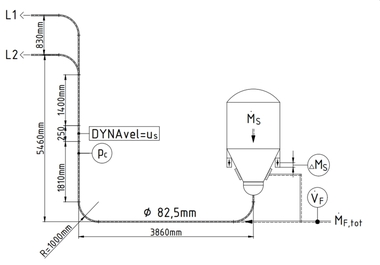

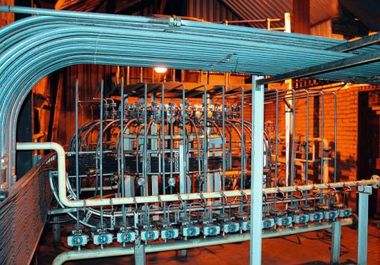

Conveying wear-intensive bulk solids is an issue in many industry sectors. Particles are conveyed much faster in dilute phase conveying. Here lower quantities of bulk solids are conveyed with a high percentage of air, sometimes at a speed of up to 90 km/h. This often leads to severe wear problems, as the bulk solids particles hit the walls of the pipe countless times during transport. Pipe bends from the Master-PROTECT series from Masterflex AG feature an inner PU lining and also have a special patented interior geometry (Fig.). The outstanding feature is the thicker section of lining precisely at that part of the bend subject to the highest mechanical loads.