News from Haver Niagara

Haver & Boecker features the Ty-Rail quick-tensioning system. The patented Ty-Rail system solves a problem of time intensive screen media change-outs. Replacing tension rails is typically time consuming and requires removing and replacing many pieces of hardware per screen section. Washers or bolts are often dropped or lost in the process, which adds to downtime and parts costs. The Ty-Rail system provides a fast return on investment, and cuts screen change-out time in half.

Industry-changing tension rail system Ty-Rail™ for vibrating screens

Each Ty-Rail package includes two tension rails, eight angle boxes and eight bolts; all the hardware required to change one screen section. Once installed, each rail becomes a singular, removable piece since the bolts remain attached to the rail, and the angle boxes remain attached to the vibrating screen. To remove the tension rails, an operator simply loosens the bolts on each, shifts the angle boxes up, and lifts the rail and bolts out as one piece. This reduces screen media change-out times by about 50 percent. Additionally, the innovation can take the task of changing tensioned screen media panels from two people down to one.

The system is designed specifically for Haver & Boecker’s vibrating screens.

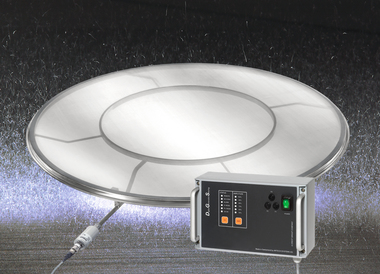

Haver & Boecker offers the Pulse vibration analysis service program

Haver & Boecker features its Pulse vibration analysis service program. This innovation in vi-bration analysis gives mining and aggregate customers a means to optimum vibrating screen performance.

Pulse is designed specifically to monitor the health of vibrating screens to ensure optimum screening performance and equipment durability. Understanding that small imbalances can lead to substantial and expensive problems, the program detects irregularities that could trans-late into diminished performance, decreased efficiency and increased operating costs for the vibrating screen. The reporting and historical tracking of the machine’s performance gives customers the information needed to minimize downtime and maximize productivity and profits.

The program was developed to be easy to operate. Components were specifically chosen and engineered for the harsh environments where screening takes place.

Pulse gives customers the hardware and software required to instantly record vibrations on their machine. That data is then transmitted to Haver & Boecker where the engineering team analyzes it. The team then issues a report back to the customer including an analysis of the machine’s performance and recommendations for improvement. If the results are good, the customer has reassurance that the machine is healthy. If the results require a Haver technician to examine the machine in person, a service call is scheduled.

The Pulse system uses an industrial-grade tablet computer that connects wirelessly with eight tri-axial sensors. The sensors attach to key places on the equipment and send up to 24 channels of data to the tablet, which displays a real-time view of the machine’s orbit, acceleration, deviations and more.

Beyond the real-time view on the screen, all of the information from the sensors is electronically stored in the database for an easily-accessible historical overview of the machine. The information can be downloaded online in two report formats. The Orbit Report provides a visual of orbit and wave form, as well as data about acceleration, stroke, speed and phase angle. Fast Fourier transformation, or FFT, plots are processed by the software for values for three channels of data for each measuring point. The Tuning Report extrapolates deviations between measurement points while providing recommendations on balance, acceleration, stroke and speed. It provides feed and discharge analysis as well as diagonal measurements.

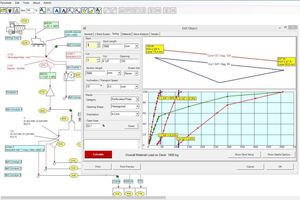

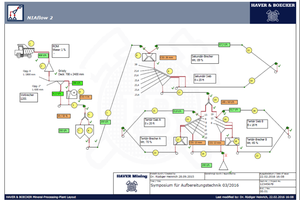

Haver & Boecker optimizes mining operations with NIAflow software

Haver & Boecker offers NIAflow plant simulation software. NIAflow helps producers opti-mize quarry and mine operations by diagramming plant flow, machine placement, product pre-calculations and more.

Developed by Haver & Boecker engineers, NIAflow instantly analyzes existing or proposed processes, records plant statuses, and recognizes potential for plant optimization. The software is available for download on Windows-based systems. NIAflow supports the user in every engineering phase, from drafting flow diagrams for product pre-calculation to plant start-up and simulating parameter changes. Its intuitive menu control makes it easy for all levels of experience, and Haver & Boecker provides several levels of training, if needed. These can be group, company or even individual training sessions.

NIAflow allows users to analyze more than 90 different process equipment pieces, from crushers and vibrating screens to material washers and conveyers. Beyond equipment, the system uses scientific-based methods to monitor the operation’s input, output and waste piles. The program calculates the mass and volumetric flow rates as well as the valuable content with machine-specific operating parameters to prevent plant bottlenecks before equipment is in place.

NIAflow is available for purchase for aggregates and mining. The NIAflow Aggregates version is the extensive, full version of the NIAflow simulation software that allows unlimited machine input. NIAflow Mining complements the Aggregates full version, but offers additional equipment options, such as classifying and sorting equipment.