Positive operating experience after separator replacement

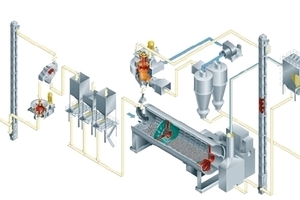

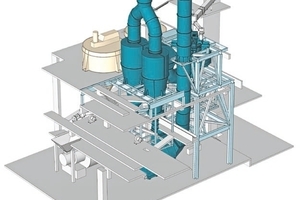

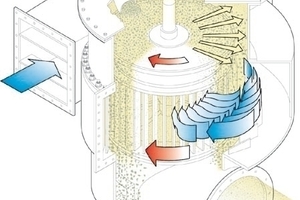

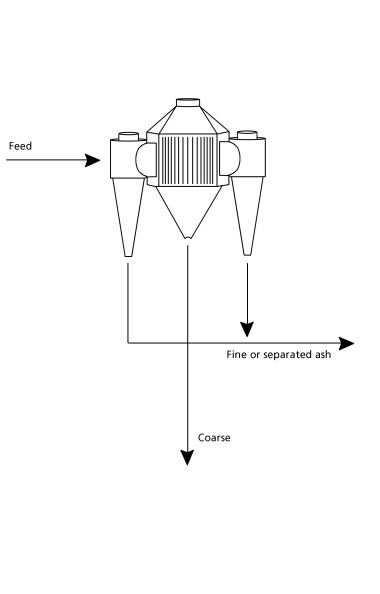

In July 2010, Phoenix Zement in Beckum optimized a grinding plant by changing the separator (see report in ZKG INTERNATIONAL 09/2010, pp. 20-23). The background to this investment by Phoenix was the need to produce high-performance cements in an energy-efficient manner in order to remain competitive and even strengthen their position. With the old system it was either impossible to produce the high-performance cements, or it could only be done at low throughput rates and high energy costs. The experience from more than one year of operation and the results of production analyses prove that the...