Eliminating weak points, optimizing production process

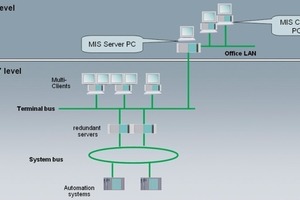

In future, HeidelbergCement, a construction material company, will be using Sicement IT MIS, the Siemens Management Information System, throughout all its locations. The MIS solution collects the operating, process and quality data from HeidelbergCement‘s production plants, and makes it available centrally for evaluation in the Heidelberg head office. The system thus supports continuous optimization of the production processes, helps to run the plants more cost-effectively, and further improves product quality (Figs. 1 and 2).

The system can collect data from various control systems and automation systems, and then process and archive it centrally. For example, the production quantity figures and energy consumptions are calculated cyclically, and assigned to the various types of cement produced. Another important function is the recording of values input manually into the system. This records, for example, the calorific values and moisture contents of fuels, and the deliveries of raw materials. All data can be visualized in the form of curves, and data from different periods can be easily overlaid and compared. A range of reports are generated in Microsoft Excel from the recorded and archived data to provide the management with the information it requires to make important decisions. Such reports include, for example, a clinker production report, the long-term energy consumption trend of a cement mill, and the long-term monitoring of clinker quality, free lime content and clinker minerals.

Another major reason for choosing Sicement IT MIS was the option of being able to archive and evaluate not only the process values but also the messages from the control systems. That makes it even easier to find the weak points in a plant. For example, evaluating chatter errors makes it simpler to detect recurrent malfunctions, or optimize the frequent changeovers and start-ups of the plant sections. This is where the Siemens Sicement Cemat control system comes into play. It contains, among other functions, a comprehensive system status and alarm message system. Integration into the Process Data Information System (PDIS) also makes long-term evaluations possible.

Process values, messages and manual data inputs are archived on a server PC. The data stored there is protected against manipulation, and independent of the control system. The client/server architecture makes all archived data available company-wide for display and evaluation, or optimization analyses. A later expansion stage will make access possible via a web-client. This will eliminate the installation

and maintenance of client software on the office computers. All employees with access to the system will

then be able to call up data and reports at all times. The transparency of production can be increased because Sicement IT MIS V7.0 tracks production precisely, and relevant information is available round-the-clock. The HeidelbergCement Works in Lengfurt acted as the first pilot. Data from two PCS7 systems and an additional Simatic S7 controller were processed and archived in the MIS there. After the pilot project has been successfully completed, the Siemens Management Information System will be introduced throughout the company.