Design of combined drying and grinding mills

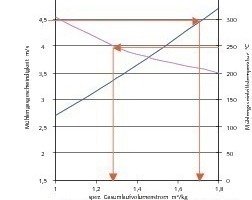

Summary: A calculation program for the design of combined drying and grinding plants is presented in this article. First the plant and process engineering data for comminution are determined. The second step covers the determination of the process engineering data of combined drying and grinding. The practical experience gained has been included in the calculation program for all process engineering alternatives which occur. In addition, the operator has the freedom to incorporate his own design and practical values as far as possible. For example, the calculations make it possible to divide the mill into two or three grinding compartments and to quantify the additional potentials of hot incoming air, if available, or the effect of an increased circulation of gas.

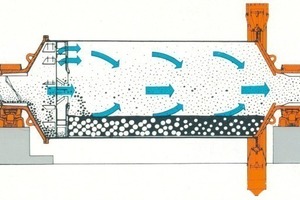

The specific feature of combined drying and grinding is that two processes, i. e. fine comminution and drying, take place in one process area. In connection with the pneumatic handling, the continuous enlargement of the specific surface and the aeration of the mill feed, this process has advantages compared to conventional drying, e.g. in rotary dryers, and is distinguished by the energetically favourable utilization of the waste heat of other technological processes.

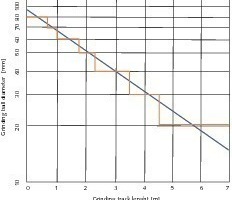

The tube mill of combined drying and grinding plants is designed according to comminution principles since the...