The next generation of surveying

The Tachymeter is a must-have for geo-desists and the portfolio of surveyors can not be imagined without it. The device, which is used for photogrammetry and initial measurement of points and which is able to determine horizontal directions, vertical angles and slants, will be complemented by the Aibot X6 (Figure 1), constructed by the company Aibotix from Kassel/Germany.

The hexacopter is an intelligent copter platform, which is distinguished by easy handling and a high degree of robustness. It was developed in order to fit the highest requirements of industrial inspections and surveys. The Aibot X6 is a revolution on the field of geo-mappings. Due to the accurate management of the camera resolution and the control of speed, direction and position, the device captures a cartographic area by reinterpretation of the conventional photogrammetry. Hence 3D-models and orthophotos will be of the highest quality.

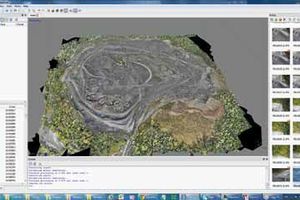

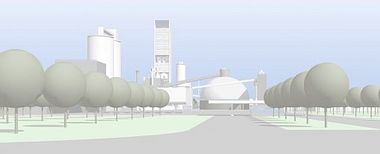

The advantages of the Aibot X6 were tested at the company Asker Oppmaling AS from Norway. Focus of the test was a stone quarry near Oslo with the size of 33 ha (Figure 2). Asker compared the ground control points which were measured conventionally with the ones taken by the Aibot X6. The results of this test are spectacular and will make the work of surveyors much easier – as well as promising an enormous time saving.

“It´s amazing how much work the X6 saves us. We can control the Aibot from a central location which saves us the strenuous walk through the cavern”, says Magnus Myhre, General Manager of Asker Oppmaling AS.

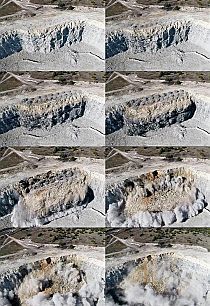

Comparing the workflow of the conventional survey method with the survey done by the Aibot X6 it´s quickly clear that the copter will be well-established in the industry. As the example of the Norwegian quarry has shown only the plain survey would take about 3 to 4 weeks. The surveyors would have to walk through the mine by foot in order to collect the data. Domains like dangerous cavities or muddy areas are very hard to access, so most of the time they cannot be measured. Unfortunately, this way some data gets lost compared to the method with the X6, where all data can be collected.

The copter with a width of 1.05 m and a height of 0.45 m is very small and can reach areas which are difficult to access without any problems. The device is able to carry an additional pay load of up to 2.5 kg and has, due to the extreme light CPR frame only an own weight of 2,555 g. The consequence of size and weight is the enormous flight stability which enables the copter to get great results even with strong wind. The symbiosis of six rotors and the powerful motor guarantee a tremendous lift and a stable flight altitude. The copter reaches a climb rate of 8 m/sec and a speed of 60 km/h. In addition the Aibot can be controlled from a central location. The area has not to be covered on foot.

Those qualities are a revolution for surveys and promise a time saving of about four times compared to the conventional method using the Tachymeter. This was shown during the test in Norway.

The workflow of mapping with the Aibot X6 is very easy. In the preparatory stage the requirements have to be defined. The ground resolution is practicable from 1 mm up to 4 mm. Parameters like flight height, speed, overlapping and distance of the trigger position can be planned in very short time by the flight planning software AiProFlight from Aibotix. The project requirements of Asker add up to an area of 33 ha and a pixel size of 22.7 mm. After the requirements have been set the actual flight plan is constructed in order to collect the data.

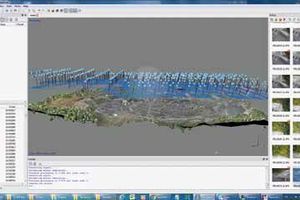

The flight planning is done by the use of the Aibotix AiProFlight Software. Flight direction, resolution, height, route and stereo overlapping will be defined and inserted into the mapping device. The flight plan will be constructed and saved by mouse click. At any waypoint (Figure 3) assignments like camera position or dwell time can be inserted. As soon as the flight plan is transferred wireless to the Aibot X6 it can operate 100 % automatically. In a normal surface flight the pictures will be taken in a 90 degree angle vertical down (nadir).

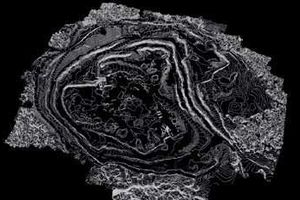

One of the unique features of the X6 is the rotatable camera mount which guarantees a flight through a stone quarry and generates an almost unachievable detailed resolution of the vertical walls in an angle of 45 degrees (oblique aerial view). Picture based 3D-modeling software like the AgiSoft or Enso use geo-referenced pictures, building the texture of an orthophoto (Figure 4) or a 3D-model (Figure 5). A cost-intensive camera calibration is not necessary. The software used has the opportunity to operate a calibration with help of the determined camera parameters additionally to the workflow.

Magnus Myhre is thrilled about the Aibot X6: “We are impressed by the Aibot X6. All waypoints are within the accurateness of the high-precision of the Trimble R8 GPS. The amount of work and time is extreme low compared to the conventional method.” The Asker crew at the quarry shared his opinion (Figure 6).

www.aibotix.com