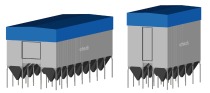

A new EMC baghouse (EMC – Energy Minimizing Concept) was installed in the Leube cement factory for about 5 million € to dedust the kiln exit gases. With the new filter, the project target value of dust emissions agreed upon with the citizens’ council of Gartenau was even undercut by more than 50%. Already in 2003 Leube had agreed together with the citizens’ council of Gartenau on a limit of 15 mg/m³ as well as a target value of 10 mg/m³ in the future. With the baghouse of the rotary kiln, which was commissioned in March 2012, the daily dust emissions are reduced to only 5 mg/m³. “On the tide of new installations and reconstructions we also could improve the mill output and reduce the power requirement. Our success is based on a sustainable energy and environmental policy. Due to this investment Leube continues to be one of the most innovative cement manufacturers”, said Mag. Rudolf Zrost, managing director of Zementwerk Leube GmbH. The last ESP still operating at Leube was replaced by a baghouse from Scheuch/Upper Austria. The strict limit had already been undercut with the ESP. “The environmentally relevant advantages of the new bag filter technology are clearly less dust emissions as well as the reduction of energy consumption”, explained Ing. Karl Linecker, project manager of Leube. “Due to the new kiln filter, the dust emission is reduced to about 12 kg per day, i.e. by more than the half”, Linecker added. Leube has worked on the reduction of emissions quite some time. Till today the emission of pollutants could clearly be reduced mainly by the carefully controlled use of substitute fuels. They are principally “cleaner” than the traditional fuels coal and heavy fuel oil, which resulted in a clear improvement of the overall emissions. Together with new filter technology, these “clean fuels” are an unrivalled combination. “Thus, we are one of the cleanest cement factories in the world”, concluded Rudolf Zrost.