Hydrogen Expo 2024 offers beacon of hope for decarbonising cement

16.08.2024As the cement industry grapples with an urgent need to cut CO2 emissions, HydrogEn Expo 2024, scheduled for 11-13th September at Piacenza Expo in Italy, will facilitate connections for cement producers to explore the decarbonisation potential of hydrogen through applications in kilns, mixtures, and carbon capture.

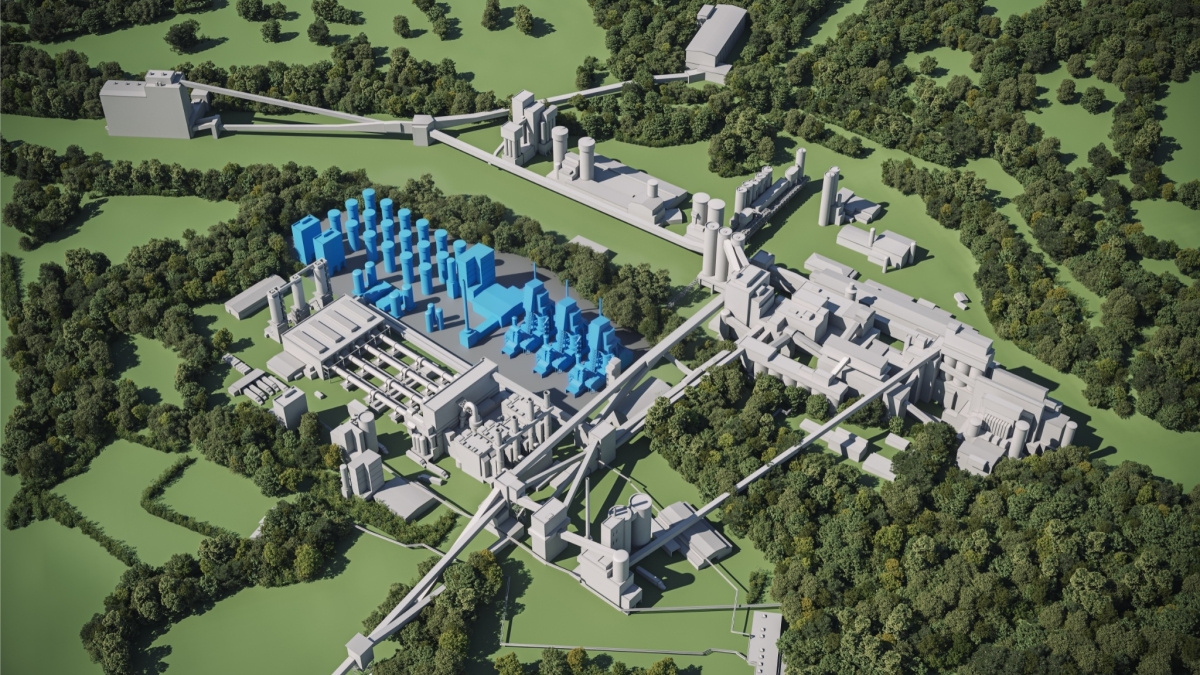

![]() Impressions from GIC 2024

Impressions from GIC 2024

All Mediapoint & Exhibitions

Decarbonising the cement and concrete industries was one of the main themes at GIC 2024 in April, with 57% of exhibitors highlighting sustainability as their customers’ top concern. Now, Mediapoint & Exhibitions, the company behind GIC, is returning to Piacenza Expo in September with HydrogEn 2024, an event dedicated to the production, transportation, storage, and use of hydrogen, including in cement production.

Between 11-13th September, more than 190 suppliers will showcase products and services for the entire hydrogen ecosystem, encompassing innovative solutions to help cement producers – among participants from other sectors – implement hydrogen technologies as an effective CO2 reduction strategy.

![]()

Why hydrogen matters for greener cement

One of the most promising uses of hydrogen is as an alternative to coal or natural gas for powering cement kilns, where the main raw materials are heated to form clinker. This process is highly energy-intensive and requires extreme temperatures that are difficult to achieve with electricity alone. Demonstrating the potential environmental benefits of using hydrogen as a fuel source for cement production, a 2022 study found a significant 44% reduction in CO2 emissions compared to traditional coal-based methods, as hydrogen burns cleanly producing only water vapour. To simplify the supply, this hydrogen could be produced on site using renewable electricity.

Hydrogen could also serve as a reducing agent in the raw materials used for cement, enabling manufacturers to use less clinker while achieving the desired properties in the final product. This would lead to fewer CO2 emissions, as CO2 is released both as a byproduct of the chemical reaction in clinker production and when the kiln is powered by fossil fuels. Research published in March this year suggested that using a lower clinker-to-cement ratio could lessen CO2 emissions by 9-15%. This reduction would lead to a considerable decrease in atmospheric carbon, given the consistently high volumes of cement production worldwide.

Finally, hydrogen could be integrated into carbon capture processes – such as oxyfuel combustion or chemical looping combustion – at cement plants to capture CO2 emissions. This captured CO2 can then be repurposed for producing synthetic fuels or building materials, contributing to a more carbon-neutral production process. A 2022 report indicated that with 95% capture efficiency, these carbon capture methods could reduce the lifecycle CO2 emissions of cement production by nearly 70%.

Considering that cement production accounts for about 8% of global CO2 emissions – 34% from energy-related and 66% from process-related sources – and the increasing demand for cement, hydrogen offers significant potential to decarbonise this sector. By reducing both emissions and reliance on fossil fuels, hydrogen can contribute to a more sustainable future for the cement industry and the planet.

![]()

At HydrogEn Expo 2024, visitors from the cement industry will encounter a range of specialised exhibitors offering valuable resources for integrating hydrogen into cement manufacturing. Attendees will find consultants skilled in navigating safety regulations and permitting processes for hydrogen use, as well as high-efficiency electrolysers designed to facilitate cost-effective green hydrogen production on-site. Solutions for hydrogen transportation and storage will also be featured, ensuring a reliable supply chain for cement plants that do not produce hydrogen on-site. Additionally, there will be exhibitors showcasing advanced carbon capture technologies.

Furthermore, the event will feature a comprehensive conference program, with details to be announced soon. By attending HydrogEn Expo and exploring these key areas, cement manufacturers can gain essential insights and connect with solution providers to effectively incorporate hydrogen into their decarbonisation strategies.

“While large-scale green hydrogen production and refining its use in cement kilns remain challenges, we are encouraged by the progress as major cement companies begin trialling hydrogen for decarbonisation,” said Fabio Potestà, director of Mediapoint & Exhibitions. “We are excited to facilitate further connections between cement industry leaders and hydrogen experts at HydrogEn Expo 2024 this September, fostering collaboration in technology development, application, and sustainability.”

HydrogEn Expo takes place 11-13th September 2024 at Piacenza Expo in Italy.