Low-CO2 lime production as the starting point for a climate-neutral industry

08.11.2023The transformation of the German industry to climate neutrality requires a pioneering technical spirit and political will. This was the main message from the three industrial heavyweights Lhoist, Air Liquide and thyssenkrupp Steel during the plant visit by EU parliamentarian Peter Liese and member of the Bundestag Klaus Wiener, both CDU, to Europe's largest lime plant, the Lhoist Flandersbach plant in Wülfrath near Düsseldorf.

Thomas Perterer, Peter Liese, Klaus Wiener, Gilles Le Van and Matthias Weinberg at the Lhoist Flandersbach lime works in Wülfrath (from left)

Thomas Perterer, Peter Liese, Klaus Wiener, Gilles Le Van and Matthias Weinberg at the Lhoist Flandersbach lime works in Wülfrath (from left)

Copyright: Lhoist

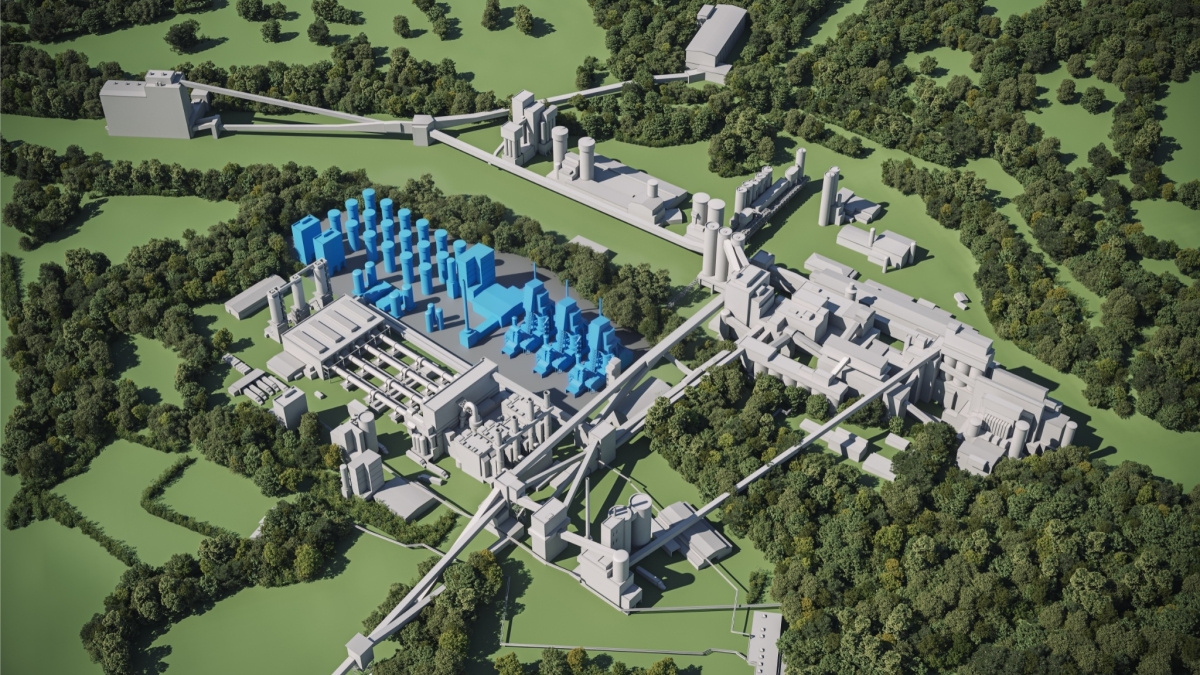

The two MPs from the EU and the federal government wanted to see for themselves the plans of the world's leading lime producer. Lhoist intends to convert the traditional site in Wülfrath into a climate-friendly facility and thus save over one million tons of CO2. The company estimates that this will require several hundred million euros in investment: For the construction of completely new types of kilns for firing limestone as well as for a CO2 capture system that collects the CO2 escaping from the limestone. In July, the project, dubbed “Everest”, was pre-selected by the EU Innovation Fund for funding in the hundreds of millions. A contract is currently being drawn up by the EU.

Thomas Perterer, Managing Director of Lhoist Germany: “Our project is an important milestone on the road to low-CO2 lime production, and the selection by the EU Innovation Fund is a great endorsement of our ambitions. And we are encouraged by the cross-party support from politicians. Now it is important that important regulatory framework conditions are created so that the project becomes a reality.”

MEP Liese confirms this will to shape the future: “With the Innovation Fund, we have created the right instrument at EU level to drive forward pioneering projects like the one here in Wülfrath. I am therefore delighted to see that our work is bearing fruit and that Lhoist wants to seize this opportunity for transformation. We can only save the climate if we make a global effort. To do this, it is imperative that we do not drive industry out of Europe, but support it in its transition to climate neutrality. Only then will we be a role model for the rest of the world.”

Klaus Wiener, Member of the Bundestag and member of the Environment Committee and the Economic Committee: “The dimensions of the project are impressive. It shows that ecology and economy can go hand in hand and that entire value chains can benefit from it,” emphasizes the long-time economist, adding: “It is now important that the federal government quickly creates the appropriate planning security for the implementation of such projects. There is an urgent need for action, particularly with regard to energy costs and the legal framework.”

Improve framework conditions and prevent deindustrialization

Lhoist and technology partner Air Liquide point out that, in addition to many legal and licensing details, the transportation and export of CO2 in particular must be made possible. The issue of CO2 storage sites must also be addressed without reservation. Gilles Le Van, Vice President Large Industries and Energy Transition for Air Liquide in Central Europe: “With our technology, we can effectively support Lhoist in managing the CO2 from the limestone. The technology is there, the industry is ready. And the associated opportunities are great. But the framework has to be right. Because the industry must remain competitive if the climate transformation is to succeed.”

Climate-neutral supply chains are crucial for the economy

According to Matthias Weinberg, Head of Competence Center Metallurgy at thyssenkrupp Steel, customer interest has long shown just how important the success of this transformation will be: “The demand from our industrial customers for green steel is increasing and we want to drastically reduce the CO2 emissions of our production as quickly as possible. That's why we are currently working flat out to implement our construction project for the first hydrogen-based direct reduction plant in Duisburg. But the decarbonization of the entire supply chain also plays a major role. We are therefore delighted about this ambitious project from our long-standing supplier Lhoist.”

Lhoist, recently nominated for the German Sustainability Award, expects to sign the funding agreement with the EU by the end of 2023. This will then mark the next milestone in the major project for low-CO2 lime production.