Eirich mixing granulators part of the Granulation Course at the University of Sheffield

07.08.2019Very few institutes and universities in Europe have in-depth expertise in granulation technology. Every year, the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) in Dresden offers basic and advanced courses for customers in the ceramics industry. The University of Sheffield stages the International Granulation Workshop every second year, which consists of a two-day Granulation Course followed by a three-day Granulation Conference. The event used to be targeted at the food and pharmaceutical industries, but the horizon now extends to all industries. The Workshop was held for the 9th time on 08.07.-10.2019. As is the case at IKTS in Dresden, Eirich mixers are part of the program in Sheffield.

Sir Robert Hadfield Building of the University of Sheffield (All Eirich)

Sir Robert Hadfield Building of the University of Sheffield (All Eirich)

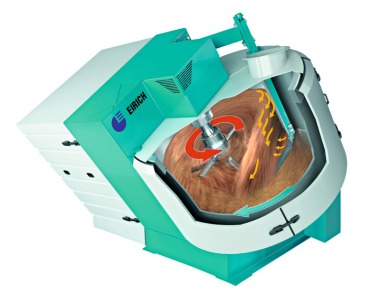

Thermal processing and mechanical processing are the two options currently available for producing granulate. The high cost of energy consumed in thermal granulation is becoming an increasingly serious problem in many industries, so companies are searching for alternatives such as pressure agglomeration, extrusion and tumble-growth agglomeration. (Roll) pressure agglomeration and extrusion (using perforated roller presses) generally do not produce round fine-grain granulate and an upstream mixing step is needed for both techniques. In contrast, mixing and granulation can take place in a single tumble-growth process using an Eirich mixer.

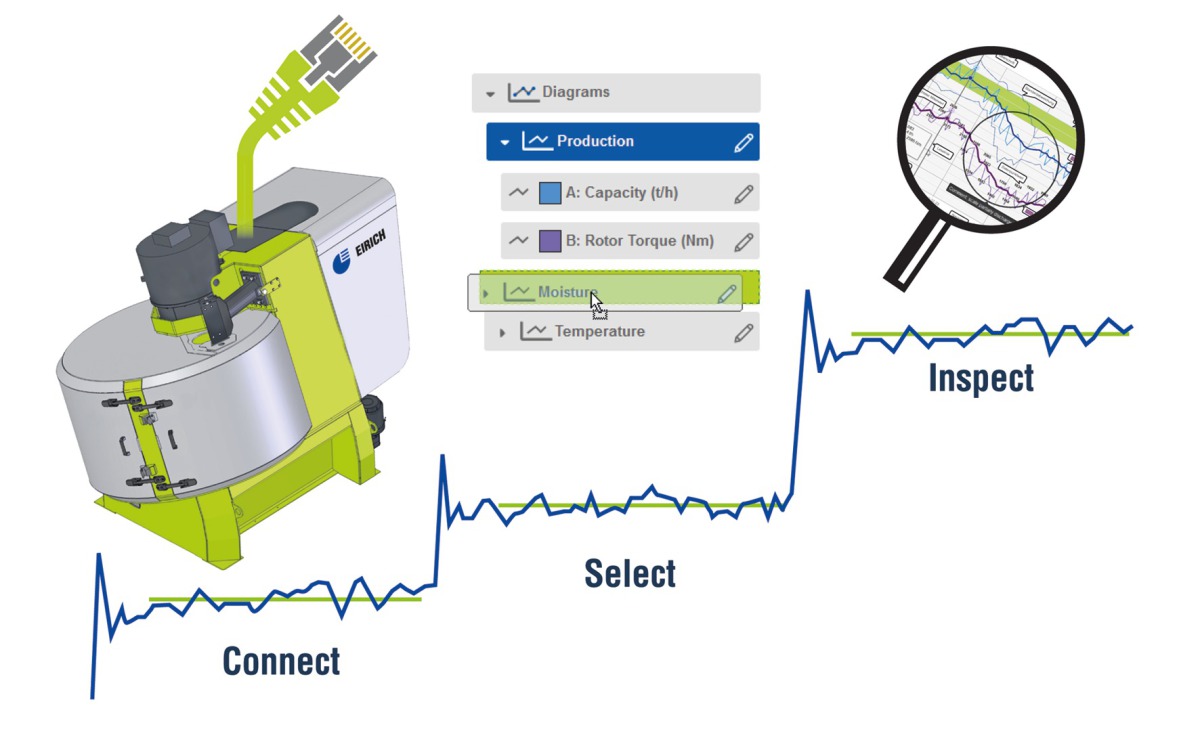

The Granulation Course with Eirich mixers

The Granulation Course with Eirich mixers

Eirich mixing granulators with capacities between 1 l and 3000 l have only one rotor tool. Larger machines have two. There is no need for the high-speed, high-wear choppers which are installed on plough share mixers. Depending on the application, the rotor can run at speed above 30 m/s. This makes it possible to generate high shear forces and quickly distribute the fluids. In a hybrid mixing process, the speed can vary depending on whether wet or drying mixing takes place prior to granulation. By running the process with different tools and at different speeds, grain size can be manipulated over a wide range. Granulate with PSD D50 between 100 µm and 5 mm can be produced depending on the material.

The produced granules

The produced granules

Eirich mixers are used as mixing granulators in a wide range of industries. The investment is relatively modest and the machines require little maintenance. The mixers also have other capabilities which companies take advantage of. Granulation can be important in the recycling industry to process sludge and dust. Granulate needs to be coated in the mixer during fertilizer production, etc.

Eirich helps users identify the cheapest/best operating conditions for the granulation process. Feasibility studies using customer materials can be carried out throughout the year at the Test Center in Hardheim and at Eirich Group sites around the world.

www.eirich.com