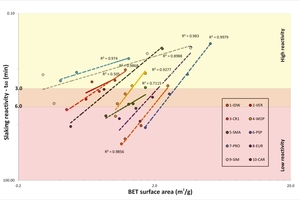

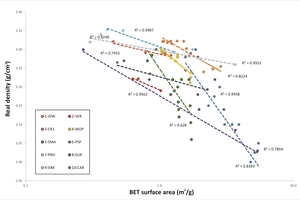

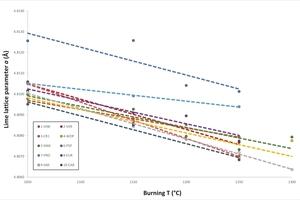

Reactivity and overburning tendency of quicklime burnt at high temperature

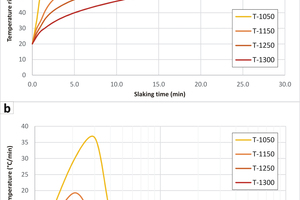

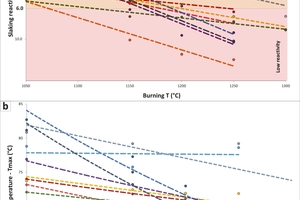

This study investigates the impact of different burning temperatures on quicklime slaking reactivity. Moreover, it reviews the state of the art of the effect of carbonate rock fabrics and calcination kinetics on the production of quicklime in industrial kilns. The burnability and overburning tendency of raw materials with different geological origin, stratigraphic positions, fabrics and compositions were investigated. Burning trials were performed on crushed rocks as received, between 1050 and 1300 °C, to simulate the soft-, medium- and dead-burning conditions occurring in Twin-Shaft Regenerative (TSR) kilns. The raw materials and burnt products were characterized based on a multidisciplinary analytical approach, including physical-chemical, mineralogical-petrographic, crystallographic and thermal analyses. The lime reactivity was determined according to the European slaking test method. By means of statistical analysis of different datasets, key factors controlling the lime reactivity and overburning tendency at high temperature could be identified.

1 Introduction

The reactivity of commercial lime became a matter of considerable interest with the introduction of the basic oxygen converter steel furnace during the 1950s [1]. The use of quicklime instead of limestone and the rapid acceptance of this technology during the 1960s caused the definitive substitution of open-hearth steelmaking furnaces, and created parallel a revolution within the lime industry [2]. Nowadays, lime reactivity plays a critical role in different industrial processes. It is especially important to make a good slag facilitating the removal of sulphur and phosphorus and...