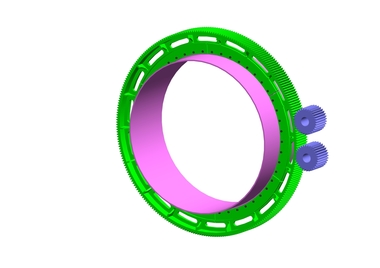

Girth gears for large rotating equipment

In the cement and primary industry, girth gears are needed for driving horizontal mills, dryers, rotary kilns and other large pieces of rotating equipment. Mounted on the periphery of the equipment, they transfer the drive torque from the gear motor to the rotary cylinder.

With this in mind, SEW-Eurodrive has engineered a flexible concept featuring optimal geometry and very good technical characteristics. It substantially simplifies the manufacture, handling and installation of girth gears. The girth gears are not of the one-piece type, but are made up several identical segments, the number of which depends on the gear’s overall diameter. This flexible approach makes them easier to transport. Their installation, too, is much simpler, whether with the aid of a spring retainer or a flange. SEW-Eurodrive makes segmented girth gears with typical pitch circle diameters of 3 to 15 m, though the applied principles of design also allow smaller and larger diameters, as well. The presently available H segments can transfer loads of 4000 to 6000 kW with one drive pinion and 6000 to 8000 kW or more with two.

Made of austempered ductile iron (ADI), these cast girth gears have outstanding material properties and are very hard wearing. Consequently, SEW-Eurodrive is able to offer narrower tooth widths than those of rival products, yielding overall cost savings for the customer. In each case, the rings are produced as customized solutions within the scope of the established product spectrum.

SEW-Eurodrive supplies not just the girth gear itself, but the entire drive package. The drive pinion can be mounted either directly on the input shaft or separately supported (pedestal bearings). Such solutions call for a lot of consulting, so SEW-Eurodrive specialists will gladly help find the technically and economically optimal solution for these and other applications.

//www.sew-eurodrive.de" target="_blank" >www.sew-eurodrive.de:www.sew-eurodrive.de