Better protection of the environment by mobile dust suppression

There are several steps in the cement manufacturing process that can create dust issues, including quarrying, combustion, milling and crushing. Many of these operations have some form of dust suppression system built in, such as cyclone collectors, electrostatic precipitators or bag houses. But controlling dust outdoors during quarrying, crushing and transportation of material can be a formidable challenge.

Trinidad Cement Limited (TCL) has been a leading supplier to the Caribbean region for more than 50 years, currently producing about 1.1 million metric tonnes annually from its 32-hectare facility at Claxton Bay on the Gulf of Paria, Trinidad. The company provides six different cement products, including ordinary, premium and specialty grades, using a wet process due to the distance between its 120 hectares of limestone reserves in Mayo and the manufacturing operations at Claxton Bay. To avoid the complication and expense of trucking or rail transportation methods, slurry is pumped more than 14 km through a 10-inch (approx. 25 cm) pipeline to cover the distance.

Like most cement producers, TCL employs a wide range of dust suppression technologies in its operations, including electrostatic precipitators on all kiln lines that remove particles as small as 1 micron, with an efficiency that exceeds 99 %. In addition, a number of strategically located bag house units employ fabric filters to trap dust from clinker, cement mill and silo operations. Cyclone separators are also located at the exhaust end of the clinker cooler sections of the cement plant and at the exit of the quarry crushers. The company uses gas analyzers and rigorous process control to monitor conditions and strictly limit dust release or migration.

The total effect is efficient control of airborne particles to protect workers and the local environment during those operations, but as with many cement plants, TCL faces a different kind of challenge before and after materials enter its fixed processing equipment. Operations such as quarrying, transportation, loading, mobile crushing and bulk storage typically don’t lend themselves to integrated dust control, and as crushed rock, clinker and cement powder dry out, they create the potential to release vast amounts of dust.

Although TCL uses dust screens and vegetation to help create a barrier and contain airborne particulates, company officials wanted to extend their ability to suppress both airborne and surface dust, without the saturation problems and manpower requirements that typically accompany hand spraying techniques. Watering with hoses or sprinklers offers limited benefit in containing surface dust, but the water droplets are far too large to have a meaningful effect on dust particles that have become airborne. Both methods have a tendency to soak the material surface and develop standing water.

TCL officials considered several dust suppression options and agreed that an atomized spray technique appeared to hold the most promise for their specific application. They contacted representatives from Dust Control Technology (Peoria, IL/USA) for detailed product information and decided on the company’s heavyweight design, the DustBoss® DB-60 (Fig. 1). The high-powered, ducted fan delivers about 850 m3 of air flow per minute, giving it a throw of more than 60 meters. The DB-60 can cover nearly 4,000 m2 from a single location, and the carriage-mounted mobile unit can be easily located wherever it’s needed most on a given day.

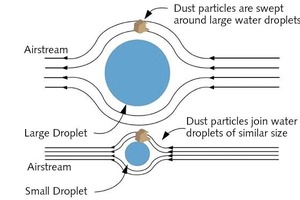

The unit’s suppression efficiency derives from its ability to balance a number of critical properties, including droplet size, spray pattern, air flow and velocity. For example, if spray nozzles produce large droplets, they can be thrown a longer distance than small ones, giving a unit more range. Unfortunately, large drops have a lower capture rate and more space in between, making them less efficient overall. The optimum condition is one in which water droplets are approximately the same size as airborne particulates, producing the greatest chance of a collision. (Fig. 2) Testing and experience have shown that droplets 50-200 microns in size typically deliver the highest efficiency in most situations.

Similarly, high air velocity allows an atomized spray to be thrown farther, so a powerful fan would seem to be an advantage (Fig. 3). But the higher the velocity, the smaller the drops tend to become. Even though small drops produce good capture and surface wetting, a point is reached at which suppression efficiency falls off in the attempt to attain greater air speed and distance. Maximum particle control is achieved by considering all of the needs and tradeoffs, producing a design that increases performance by optimizing each component in relation to the others.

The greatest opportunity to improve dust suppression at TCL was at the site’s mobile crushing unit. The company uses one of the largest tractor rippers in the Caribbean, the Caterpillar D11R, to extract raw limestone for production. The quarried stone is transported by truck to a Hazemag impactor with a capacity of 530 tonnes per hour, which crushes the rock to an average size of 25 mm.

To control the airborne dust generated from crushing and transporting, the DB-60 employs a series of 30 specially-designed brass nozzles to atomize the water, then launches the droplets with a powerful 18 kW fan. Equipped with a 7.5 kW booster pump to increase water pressure as much as 10 bar from a 2-inch supply hose, the DB-60 has an adjustable elevation from 0-50 degrees, and the oscillating head delivers 40 degrees of motion for outstanding coverage.

The results at TCL have been excellent, and the versatility of the dust control design allows crews to quickly adjust positioning, throw angle and oscillation to accommodate specific work sites and weather conditions. With the significant reduction in airborne dust, TCL is helping to ensure a healthy workplace and safeguard the environment. The move also minimizes the opportunity for abrasive dust to enter air intakes on heavy equipment, extending air filter life and reducing the potential for unnecessary wear. Crews run the DB-60 whenever the mobile crusher is operating, blanketing material piles, storage areas or truck paths to best suit the day’s work load and wind conditions.

Effective dust containment is considered an important element of TCL’s process on several levels. In addition to the health and environmental issues, significant levels of airborne dust can contribute to higher equipment maintenance costs, reduced visibility, strained community relations and even explosion hazards. The regulatory landscape in Trinidad also continues to evolve, with new and emerging legislation likely to dictate a need for improved dust suppression and containment in many industries. The Draft Air Pollution Rules of Trinidad and Tobago already have applicable sections, as does the region’s Occupational Health and Safety Act. TCL is also certified as fully compliant with ISO 14001: 2004, the most widely recognized set of environmental management standards in the world.