Modern cement production – with tradition

The 2011 ZKG technical student excursion took the ZKG INTERNATIONAL team, with interested students, on a visit to the Höver cement plant (Fig. 1). Cement has been produced here for more than a hundred years and sustainability always had and still has a special significance. Much has changed since the plant’s beginnings, however. The tenth anniversary of the plant’s blast furnace slag granulation facility at Salzgitter was celebrated in 2008, together with the 100th “birthday” of the overall location. The plant has its own harbour on the Mittelland Canal, which is also used for delivery of blast furnace slag. This material is supplied from the harbour to the plant “just-in-time” by road, with extremely short cycle times, and fed to the mill mechanically via tipper hoppers. The transition to composite cements started early at Höver. “There have already been whole months where we supplied more CEM III than anything else”, notes Marius Seglias, the Höver plant manager.

More than a century of cement production would not have been possible without the continuous focus on further development at Höver. In 1998, the plant was one of the first in Germany to change its main filter from the electrostatic to the bag filter type (Fig. 2), an innovation subsequently also applied to the bypass filter in 2003. Höver was, in addition, one of the pioneers in the automatic transmission of emissions data to the offices and authorities.

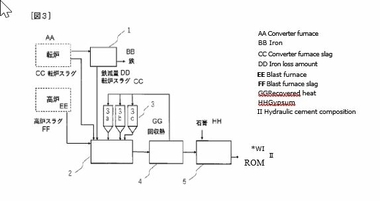

The feed material used for cement production here is calcareous marl; this is extracted at a rate of up to 10 000 t/d at two locations in the Höver quarry. Excavators feed it into high-capacity mobile crushers. The crushed material is then conveyed on belt conveyors to two feed material blending beds, which use the chevron method (Fig. 3). This marl has a residual moisture content of around 14 %; fluctuations in composition can be corrected using sand, serox or an iron component. The material is fed to the raw materials mill, a Loesche vertical roller mill, where it is comminuted and simultaneously dried using waste heat from the heat exchanger. The raw meal is separated out on a bag filter and then routed to the 10 000 t raw meal silo. From here, it is conveyed on bucket conveyors to the preheater, which is of the twin-train four-stage type (Fig. 4). The feed material has already been deacidified to a high percentage when it leaves the preheater. Residual deacidification and sintering take place in a KHD rotary kiln. Life-expired tyres and filter-press cake are fed at the kiln inlet; the main burner combusts coal, shredder fluff and animal meal. The substitute fuels rate is currently around 70 %. Holcim, with Geocycle, is well positioned for expansion of the use of substitute fuels.

The kiln’s satellite coolers were replaced by an IKN oscillating grate cooler around three years ago (Fig. 5). The criteria for this decision were enhanced efficiency, the potential for using the waste heat for drying of ground granulated blast furnace slag (GGBFS), and the reduced servicing and maintenance costs. Natural gas had previously been used to dry GGBFS. The clink-er is stored downstream of the cooler in two clinker silos, which feed two two-chamber mills for cement grinding. The returns from the mill classifier, the so-called breeze, are returned to the grinding circuit via a recirculation bucket conveyor. A large portion of the cements sold at Höver is even now no longer made up of purely Portland cements, but rather of composite cements. GGBFS is separately ground and blended to make various cement grades in the blending facility. The bag shipment rate is around 10 %, the remainder being delivered by automated silo vehicles.

Great importance is attached at Höver to the conservation and passing-on of know-how. Experienced employees continue to contribute their knowledge until reaching retirement age. Many modernisation and optimisation projects at Höver are tackled using internal resources; there was, for instance, much internal input in the development of the modern control system, which is based on an ABB 800xA core. Processes are monitored at Höver using ultra-modern methods (kiln-shell scanners, spectral analysis, thermographic cameras, etc.). Despite all this technology, however, the focus is always on people. “The experience possessed by the control-room operator, our craftsmen and our plant foremen remain indispensable for us, irrespective of all our technology”, continues Marius Seglias. “That’s why we attach so much importance to continuous and high-quality training for all our employees. Many projects can be successfully developed and completed only thanks to the personal input and commitment of the people working on them”. This is also why knowledge transfer ranks so high at Höver, in the form, for example, of internal company training courses, known as “know höv” (= know-how at/from Höver). These courses are backed up by practically orientated activities, in the laboratory, for example; here, employees learn, with a practical orientation, what quality criteria are determined, why they are so important, and how they can affect quality changes on site. Courses organised by the German Cement Works Association (VDZ), the Chamber of Commerce, suppliers and the Holcim group are also used to further staff development.