New drive system for vertical mills

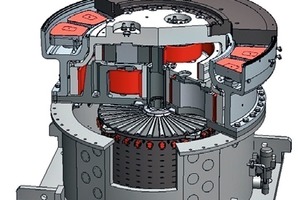

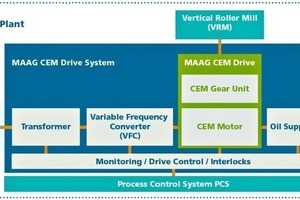

FLSmidth MAAG Gear AG of Winterthur/Switzerland is launching a new drive concept (Fig. 1) at the Hannover Messe trade fair. In the novel, integrated and modular MAAG CEM Drive, this company combines the advantages of proven MAAG gear technology with an ingenious motor concept, all inside one common housing (Fig. 2). The MAAG CEM Drive – Central Electric Motor – forms the centerpiece of a modern, energy-saving drive system for vertical mills with a power range of up to 8000 kW. FLSmidth MAAG Gear offers the unique integrated drive system (Fig. 3) from one source. It includes the following subsystems: motor combined with gear unit in the MAAG CEM Drive, transformer, frequency converter, lube oil system, and control system. In the all-in-one package, all components are perfectly matched for compact efficiency.

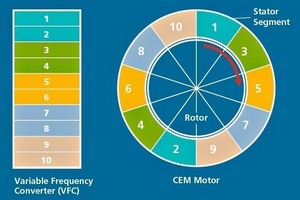

A permanent magnet synchronous motor with loss-optimized single tooth winding is the centerpiece of the MAAG CEM Drive. The use of permanent magnets reduces rotation loss to a minimum and the structure, comprising individually controlled stator segments, allows optimal power adjustment and high standardization at the same time (Fig. 4). Over a wide speed range, the adjustable drive provides a constant torque with unchangingly high efficiency. The segmented structure means that even if an individual segment fails, the motor can still be operated. The integrated motor concept offers the mill operator cost-related advantages: it is possible to dispense with an additional foundation, as no external motor is required. The absence of a motor coupling saves laborious configuration work. Moreover, no extra maintenance drive is required.

The CEM Gear stage meets the usual high MAAG standards. It is an enhancement of the proven PV stage (planetary stage with output split) from the well-known WPV gear unit. The motor and gearing are coupled on a single axis. The bevel gear stage formerly used is no longer required. The planetary stage has smooth-running, maintenance-free plain bearings. Its reduced height and compact structure guarantee compatibility with many common mill types. This also makes the MAAG CEM Drive an ideal solution for replacement projects.

The transformer and frequency converter are optimally harmonized with the local conditions. The modular structure and robust design offer high operational safety and reliability in the rough cement surroundings. By the use of environment-friendly, low-maintenance dry transformers, elaborate safety measures are a thing of the past.

The frequency converter, as a pre-assembled container solution, is quickly installed and ready for use on site. Consisting of a modular assembly of identical, compact, individually switchable modules, it ensures continuous operation. The mill speed is infinitely variable, so as to always meet the respective production requirements. Soft start and slow turning of the mill during maintenance work are possible. The converter operates at low voltage (690 V) and the high timing pulse frequency of 4 kHz enables immediate torque adjustment. The optimal harmonization of components minimizes circuit feedback. Thanks to the IP65 protection class, and tested under the most strenuous operating conditions, the converter also works in the direct vicinity of the mill.

The common oil unit is based on well-known and proven technology and ensures cooling of the motor, as well as lubrication of the gearing. As only one such unit is necessary, the management of operating supplies and replacement parts is considerably simplified.

A comprehensive network of sensors allows monitoring of critical factors and enables quick adjustment of process parameters by means of the direct connection to the process control system. With the online monitoring of the drive train, non-scheduled downtime can be reduced to a minimum.