VDMA – construction equipment and building material machinery: positive trends continue

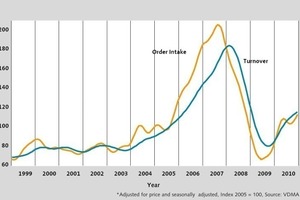

In 2010, the German construction equipment and building material machinery industry saw a growth in turnover by 13 % to 10.6 billion € (Fig. 1). Of these, the construction machinery sector made 6.3 billion €, whereas 4.3 billion € were made in the construction equipment, glass and ceramics machinery sectors For the current year, the industry is expecting to see growth of another 10 % in both areas.

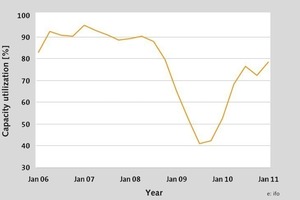

In total, 2010 was a better year for the companies than they had expected (Fig. 2). Differences were significant, however, when comparing the different segments with each other. Whereas sales of earth moving machinery, with a growth of 25 % and of road building machinery with a growth of 38 % have significantly developed, things did not go so well for the building construction machinery and for concrete technology with 10 % less sales. Manufacturers of building material machinery also saw a slight growth in turnover albeit by 1 % only.

However, with regard to incoming orders there is a different development. Already during the second half of last year, demand grew significantly in all areas. Manufacturers of construction equipment currently have 56 % more incoming orders, whereas in building material machinery there are 34 % more than in the same period in 2010.

Capacity utilization also developed positively. On average it is at about 80 % for the entire industry. The fact that most companies retained their regular staff during the crisis is now of a great advantage. The only factor slowing down these positive trends is the supply industry. Some components see lead times of 25 to up to 32 weeks. Some manufacturers in the construction machinery industry already fear not being able to fulfil some of their projects. In addition to some components being in short supply, the high prices of raw materials, steel and natural rubber fully affect the construction machinery manufacturers.

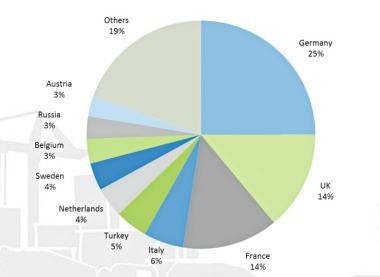

The current push comes from abroad. It is China and India in particular where things are booming, but also the Middle East as well as Brazil are setting trends. Russia, the most important market in the industry on Germany’s doorstep, although it has an enormous demand, it is currently in a waiting position. Demand within the industrialized countries is still restrained and likely to stay like this mid-term, according to experts. Times when Europe, North America and Japan together made up two thirds of the international demand for construction machinery are over. Already today nearly every second construction machine which is being produced worldwide is sold to China.

The shift in markets promotes the internationalization of companies and, at the same time, their localization in booming regions. “It is not enough to offer sales activities only“, says Klaus Beer, managing director of Hazemag, a middle-sized manufacturer of building material machinery. “You also have to produce where the markets are.” Dülmen-based Hazemag have production sites in China, North and South Africa and are currently opening a production site in Brazil. Today, statistics on foreign trade and export quota are only one indication for how widely international the German construction equipment and building material machinery industry has already become.

Companies and clients worldwide have to meet several challenges from 2011 onwards: changing markets and high environmental standards, such as the new exhaust standards, which have to be met especially by mobile machinery to be used in Europe and North America, for example. The next exhaust level 3b for mobile machinery will come into force this spring. Then, a wide range of new models will enter the European market after companies having carried out extended time- and cost intensive developments. Manufacturers are therefore expecting some of their clients to move investments forward and have already now decided to go for the ultra-modern and environmentally friendly machines. Eventually, clients in Europe and North America will have to go along in any case as only the low-emission models will be offered on the market mid-term.