Feeding equipment for a modern dry kiln line

In spring 2008, the Lafarge Wössingen Zement plant (Fig. 1) in Germany began the conversion of its production process from the semi-wet to the energy-saving dry process [1-5]. The project was completed in 2009 after only 17 months, the clinker quality was improved, the emissions were significantly reduced and the fuel mix was optimized. FLSmidth Pfister supplied the continuous gravimetric dosing systems for a range of fuel and dust feeding applications.

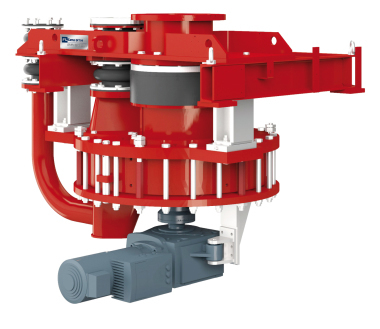

For the kiln firing, FLSmidth Pfister installed two pulverised coal rotor weighfeeders DRW, one for the main burner and the other for the calciner burner. They are operated at a feeding rate of 2-4 t/h at a feed distance of 30 m total (main burner) and 0-1 t/h at a feed distance of 80 m in total (calciner burner). The Pfister DRW (Fig. 2) is a rotor weighfeeder especially designed for dosing pulverized fuels such as petroleum coke, lignite, coal dust or oil shale in cement burning processes. Integration of material extraction, weighing, dosing and material transfer into the pneumatic conveying line makes it a compact system that provides accuracy and constancy. Powered by the innovative dosing strategy ProsCon®, the mass flow is controlled proactively before the material is discharged from the feeder.

Three multi-fuel rotor weighfeeders, two Pfister TRW-S (Fig. 3) for pneumatic feeding of high caloric fuels to the main and calciner burner, and one Pfister TRW-S for medium caloric fuel for the gravimetric feed into the calciner burner, are included in the alternative fuel installation. The Pfister TRW-S rotor weighfeeders allow a feed rate to the calciner burner of about 2-4 t/h and 7-10 t/h at a feeding distance of 140 m in total. The main burner that is fed via the Pfister TRW-S rotor weighfeeders has a feed quantity of about 1-2 t/h at a feeding distance of 80 m.

With its multi-fuel concept the rotor weighfeeder Pfister TRW-S/D offers a future-oriented technology. With only one system extremely light or heavy, fine or coarse products or even potentially explosive bulk materials can be dosed. Examples are FLUFF, RDF, sewage sludge, plastics, wood chips or animal meal.

The new kiln feeder allows a feeding rate of 150 t/h. For the raw meal and kiln dust dosing, two rotor weighfeeders FRW (Fig. 4) were installed for highly accurate pre-heater feeding. Kiln filter dust feeding is performed at 1-3 t/h. Furthermore, six rotor weighfeeders FRW feed the collected bypass dust and gypsum into the cement mill to ensure precise mill feeding for high quality cement production at all times. The bypass dust feeders (Fig. 5) are designed for a feeding rate of 0,5 t/h each and can be operated up to a chloride content of 13 %. The cement mill capacity is about 70 t/h. Two Pfister DFM flow meters are installed at the raw mill to control the flow of raw meal from different storage silos.

Whether kiln feeding or additive feeding to the raw or finish mill, the robust design of Pfister FRW rotor weighfeeders is ideal for dosing powdered bulk materials such as raw meal, fly ash, bypass- chloride- or kiln dust or cement products with high dosing constancy and precision. Due to the integration of material extraction, weighing and dosing the system is easy to operate and thus extremely reliable.

“The FLSmidth Pfister installations show a high reliability and a good accuracy. Calibrations were easy to learn for our electrician. After two years of operation no significant wear is visible”, states Stephan Schenk, Manager for Maintenance and Development in Wössingen. He continues: “The weighfeeder for middle caloric alternative fuels comes to its limit only when the fuels are out of spec, for example, if they are too coarse or if wires are too much or too long. The same is valid for the dosing of bypass dust. When the chlorine content in the dust is too high, clogging can start to create problems.”