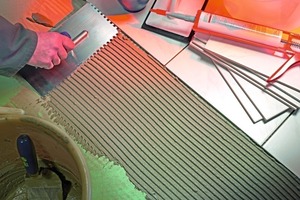

Control additives influence the filler recipe

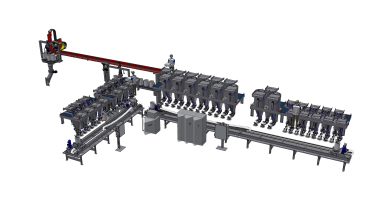

Summary: Control additives and small components are decisive parameters for the high-quality and efficient production of fillers and other construction chemical products. AZO has developed a concept for Pufas, in which all components required for the recipe are integrated, starting from the product feed from sacks to big bags and containers, a dosing and weighing unit and the precise weighing of batches, with verification of the recipe composition. With a pressure pulse conveying system the precisely weighed batches are then conveyed over a distance of 70 m into the bulk quantity mixing system. The automatic feeding system provides inventory transparency, data regarding the quantities produced and a quick ROI (Return on Investment).

The Pufas Company in Hannoversch Münden/Germany is a very innovative owner managed medium-sized business. Pufas has a core business alongside painters‘ filling that also includes adhesives, fixings and undercoats as well as a complete renovation programme in its product range. Control additives and small components are decisive parameters for high-quality and efficient production, since they essentially control the recipe of fillers. A high dosing precision is indispensable for a clean recipe composition. According to Gerhard Jordan, managing director and...