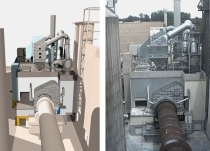

The plant manufacturer as service partner

Summary: By example it is shown how the plant manufacturer can help to minimize the plant stoppage period required for component change-outs and the performance of repairs, thanks to his know-how as the supplier of machines and systems for kiln and grinding plants. The example concerns the refurbishment of a kiln plant equipped with a satellite cooler within the agreed time period, within the specified budget, to a high quality and – of great importance – without any accidents. The service package included the flat-rate installation of plant components, surveying of the rotary kiln and a mobile machining service for key components that could be reused. The refurbishment was performed on the basis of a detailed appraisal of the plant that was carried out on site before the order was awarded.

The European cement and primary industry has to cope with increasingly limited financial and personnel resources. Owing to the global financial crisis, it is at present hardly possible to finance cost-intensive new plants, so that existing plants are being subjected to greater production demands than in the past. The core equipment of the plants is often operated to the very limit of its rated service life or even beyond that. In addition, the high pressure of cost is forcing plant owners to fully exploit the performance reserves of the equipment, while...