Cement additives based on PCE

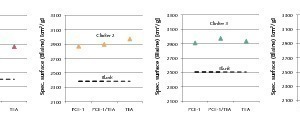

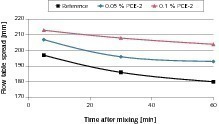

Summary: The rising demands on modern cements require continuous development of cement additives. Polycarboxylate ether (PCE), although used around the globe as concrete admixtures, remain largely unknown for the use in cement. This article examines the effects of PCE cement additives on the basis of a series of tests performed both in laboratory and on industrial scale. The use of these additives allows a more efficient grinding, systematic control of cement quality and the addition of higher percentages of clinker substitutes.

Additives have been used in cement grinding since the 1930s. Initially, the main purpose of their use was to increase the production rate, whereas substances which additionally raise the strength of the cement have increasingly come into use from the 1970s onwards [1].

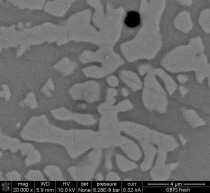

A trend towards reducing the clinker factor of cements, and thus enlarging the amounts of clinker substitutes used – such as GBFS, fly ash and limestone – is observable around the world [2]. The quality of such “composite” cements depends to a very great extent on the type and quantity of the clinker substitutes...