New kiln line: phase 3*

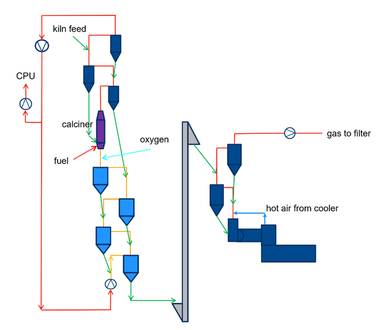

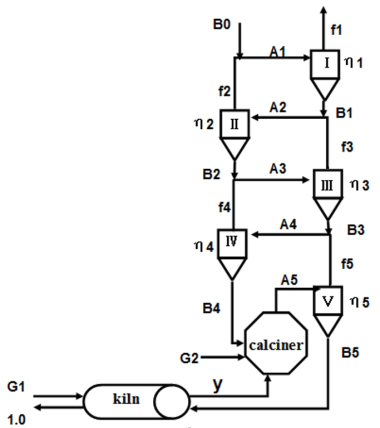

In July 2009 the groundbreaking ceremony for a new kiln line was held at the LEUBE/Austria cement factory [1]. The aim of the modernization is to secure the cement production location, to reduce pollutant emissions and to lower the energy consumption (Fig. 1). The overall technological concept and the progress to the end of 2009 were already described in a report in ZKG INTERNATIONAL [2]. This article presents the current progress status of the modernization project (as per 17.06.2010).

Erection of the steel structure and platforms of the lowest cyclone stage (+42 m) recently commenced. At the end of June the 42 m platform will be complete and then the remaining five platform will follow at intervals of 2 – 2.5 weeks. As soon as one platform is completed and the floor plates have been laid, work starts on the platforms beneath it with the installation of the refractory materials and auxiliary systems (compressed air, electrics, water, etc.). A 100 m3 raw meal hopper will also be installed in the preheater tower in order to

buffer short-term failures (up to about 1 hour) of the raw meal conveying equipment. Up to now, the planned construction concept has gone very well. One of the decisions that proved to be good was to employ an external concrete shell and an internal steel structure, and thus to utilize the advantages of both types of construction.

The kiln supports have already been completed. Rotary kiln No. 1, which had been in operation since 1960, has been shut down. It will be completely disassembled, refurbished and reassembled as rotary kiln No. 3 by the middle of August (Fig. 2). This also involves shortening the kiln from 3.6 x 50 m to 3.6 x 45.5 m. This is partially due to a recalculation of the kiln statics and partially results from the desire to reduce radiation heat losses. The outlet section will be completely replaced, while all the other components will be refurbished and sand or water-blasted. After reassembly of the kiln, the new refractory lining will be installed. The actual switchover from rotary kiln 2 to rotary kiln 3 is due to take place in calendar weeks 39 & 40. This involves shutting down kiln 2 and reconnecting the meal and gas ducts to kiln 3.

The steel structure of the clinker cooler is complete and already encased with trapezoidal plates. The cooler itself (Cemprotec) has been ready since March. The cooler exhaust air filter is not a hot gas bag filter, but has an upstream tubular cooler (air/air cooler). This constellation e.g. enables heat to be recuperated for plant consumption (1.5 MW). The advantages are higher operating reliability and lower wear, i.e. no problems with abrasion and blockages caused by clinker dust. However, a slightly lower efficiency due to the second heat transfer has to be accepted. The refractory lining design places great emphasis on small field sizes of max. 800 x 800 mm, and even 600 x 600 mm in critical areas. Brick lining is used for round areas. But even with this design it is necessary to install steel supporting brackets every 2 m in order to provide a good overview of areas that need to be relined. At the end of June, preassembly of the dedusting system commenced, with laying of its concrete foundation taking place simultaneously. In the second half of July, the system will be erected on the foundation. Clinker conveying equipment for the new line will be installed in the basement.

The exhaust gas from the new kiln will be supplied to the existing raw mill 5 (LM 27.3, 120 tph). The mill and the electrostatic precipitator are adequately dimensioned to assure the raw meal supply rate. As a height difference of +3.5 m has to be overcome over a distance of 45 m, a pneumatic system with a conveying capacity of 180 tph was selected for a section of the conveying distance. The feeding of raw meal will then be handled by a belt bucket elevator.

One interesting solution for the raw meal feed system was thought out by the experts from A Tec and Leube. The raw meal will be symmetrically fed into the riser duct via two scales. This will make it possible to weigh a portion of the raw meal and divert it to the second cyclone stage. In case of need, this constellation will enable operation with higher exhaust gas temperatures, so that raw materials with higher moisture contents can be safely ground.

The new kiln line is to be equipped with a comprehensive flame evaluation system. At present, a camera for lateral thermography is undergoing trial operation. In addition to frontal thermography we are also considering determination of the secondary air temperature by means of a further camera above the fixed grate of the cooler. This would provide the basis for a cooler secondary air control system.

* Previous parts:

[1] Investment in the future, ZKG INTERNATIONAL 62 (2009), No. 9,

pp. 46–48.

[2] Kiln system upgraded to present state of the art, ZKG INTERNATIONAL

63 (2010), No. 1, pp. 33–37