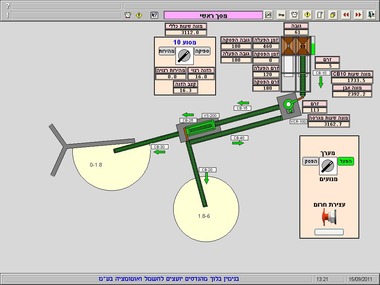

On-target fine crushing of limestone

At the production facilities of Trollius, a lime and ballast supplier in the Upper Palatinate region of Germany, both an efficiently operating plant control system and reliable process visualization play a key role. Machinery and equipment at the facilities are always state- of-the-art thanks to ongoing investment in replacements and extensions. Since August 2009, a Metso cone crusher of the type Nordberg HP100 modular (Fig.) has been in operation for recrushing the wet mix aggregate grades. At the company’s Lauterhofen plant, the focus is on processing limestone, for example to wet mix aggregate and high-grade chippings. Originally, an impact mill was used to recrush material to high-grade chippings. With an increasing demand for 2/5 and 5/8 grades, the impact mill produced too much unsaleable 0/2 sand. To produce much more target-size product – especially the 5/8 grade – with far less sand, the company decided to crush a sub-stream of the wet mix aggregate fractions 8/16, 16/22, 22/32 and 32/45 in a crusher specially suited to this purpose.