Lafarge accelerates its innovation strategy

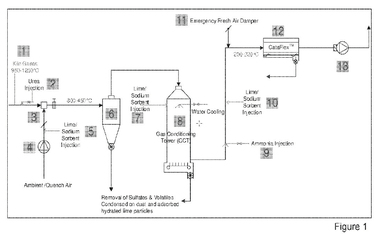

Aether, an innovative project developed by Lafarge to reduce the CO2 footprint of cement, is receiving support from the European Union. This support is provided under the European “LIFE+” program, a financing instrument supporting environmental projects. Aether has been developed in collaboration with the Institute for Building Materials in Poland (MBM) and the British Building Research Establishment (BRE). It will contribute to continuing the reduction of the Group‘s CO2 emissions. Aether deals with a new clinker formulation to cut CO2. It has been tested in the laboratory, as well as in an industrial kiln, and has demonstrated its full potential. Results show that Aether could represent an alternative to traditional Portland cement offering comparable technical properties, manufactured in a traditional cement plant kiln after just a few modifications, and leading to a lower overall environmental footprint. Aether is a new clinker chemistry in which the level of limestone is reduced and therefore the proportion of gypsum, clay and bauxite is increased. It provides a 25 % reduction in CO2 emissions and reduces the firing temperature required for the chemical reaction to occur (~ 1300 °C), providing a 15 % reduction in energy consumption.