Short mixing time due to reduced mixer length

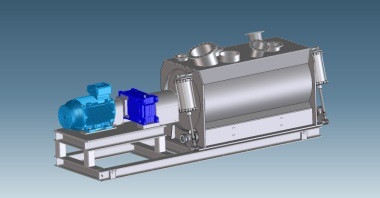

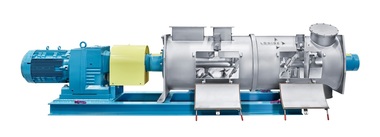

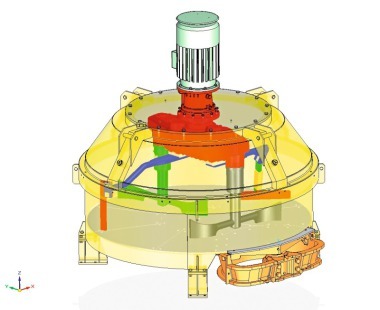

Since the invention of the ploughshare® mixer (Pflugschar®- Mischer) Lödige has continuously further developed the mixing technology. For decades this mixer has been considered to be the synonym for excellent mixing quality. With the patented EASY CLEAN (Fig. 1) Lödige now presents a mixer concept for free-flowing bulk solids and, thus, particularly for applications in the building materials and minerals industry. The many requirements with regard to residual discharge, cleaning, mixing quality and mixing time have been met consistently during the development.

The pivotal innovation of the EASY CLEAN is the reduced mixer length with simultaneously enlarged diameter (Fig. 2). The total volume has not been changed. This new proportion of the mixing drum led to some improvements in the design. The size of the discharge flap has been maximized and occupies almost the entire floor area. Dead zones were avoided. The large inspection door is a further improvement as regards cleaning and maintenance. An extremely quick but still checkable discharge is achieved due to the optimized discharge flap. The production residue is less than 1 ‰.

The mixing time is clearly lower due to the short design. Amongst other things, this is due to reduced axial transport of the material being mixed. For example, when adding 2 kg of paint pigment to 1000 kg of ground limestone, after 30 s a mixing quality was achieved the standard deviation of which was below the measurement tolerance of the analysis process (CIELAB colour system of order). This test shows that coloured chemical plaster can be produced within a mixing time of 30 s using EASY CLEAN. Deliberately no sand was used during this test in order to avoid an undesired mixing support due to coarse sand. In practice the shortened mixing time may also mean that the same output can be achieved with a smaller and, consequently, more cost-effective mixer.

The application of EASY CLEAN is focussed on mixing dry materials. Nevertheless, it is also possible to incorporate liquids into the material being mixed without any problems. The mixer can be equipped with choppers to support the mixing effect, to dissolve lumps or for granulation purposes. The standard sizes are 450 to 2000 l. For applications in the building materials field they have a total volume of 1450 l and 2000 l (useable volume 360 l to 1000 l or 500 l to 1400 l, respectively).

Gebrüder Lödige

Maschinenbau GmbH,

Paderborn/Deutschland,

Tel.: +49 5251 309-0