Sandvik

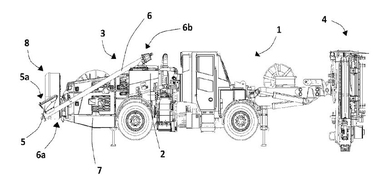

With granulation systems for applications such as foodstuffs, sub-cooling melts, thixotropic, abrasive and corrosive products, Sandvik offers the widest range of process solutions in this field. Two examples – the Rotoform 3000 and Rotoform HS (High Speed) models – will be the focus at the company‘s POWTECH stand and will be demonstrated as a steel-belt cooler in action (Fig.).

The “Rotoform family” comprises nine different types and has been developed for very specific applications, but all models work based on the same fundamental principle. With this very flexible high-tech process, melts up to a feed temperature of 320 °C and a viscosity of 50 000 mPas can be processed. Depending on the product, pastilles in the size range from 1 to 30 mm can be made. The diameter of the pastilles can be changed by simple adjustment of the feed device during ongoing operation or – in the case of more major changes to the diameter – by switching individual machine components.

Hall 7, Stand 7-425

www.sandvik.com