Quality is more than just a promise

bauma 2010 Hall B2, Stand Nr. 131/232, Munich/Germany (19.-25.04.2010)

At the bauma 2010, the innovative HAVER SCREENING GROUP presents HAVER & BOECKER on a newly designed 400 square meter stand in the form of a gigantic pelletising plate. The pelletising plate, with a diameter of 7.5 m and a capacity of 150 t/h, is designed for the automatic pelletising of fine iron particles and other fine mineral materials (Fig. 1). The technology also can be used in other fields such as the granulating of fertilisers.

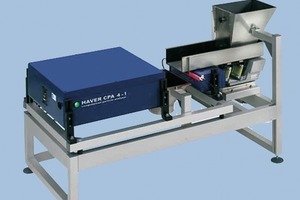

Analysis and documentation of individual production steps and processes are essential for the verification of product quality. HAVER & BOECKER not only wishes to promise quality, but the company also confirms this in its day-to-day operations. The importance of analysis and quality control at HAVER & BOECKER has led to the development of its own analytics group. The group is as wide ranging as the HAVER Group itself. The possibilities for analysis and quality testing range from wire mesh checking to the development of processes for determining particle size (Fig. 2), and extend to analysis equipment for determining flow behaviour of solids and the air-flow characteristics of packaging materials. The chemical and physical assessment of customer products is an important element in designing packaging and material handling machines. Quality through analysis means having and using the right laboratory equipment.

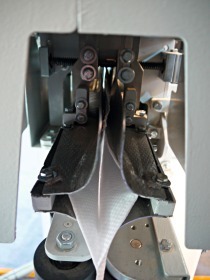

Furthermore, customer demands for packing technology have undergone profound changes (Fig. 3). In the past, requests for durability, operational reliability and long machine lifetimes were the focus of attention. But today customer demands also include higher speeds, cleanliness, weighing accuracy, high levels of product protection, ease of operation and ease of maintenance and now there are also the demands for environmental protection, energy savings and new types of packaging materials.

These demands can be met us-ing the HAVER INTEGRA® and ROTOSEAL® system and the proven valve-bag for small and large outputs. In addition it is now possible to fill powder-type building material products and minerals into watertight PE bags, which ensure far greater product protection. This was made possible by combining a new machine concept together with a new bag concept. This technology is presented under the names of THE ADAMS® and THE BENJAMIN®. THE ADAMS® is a rotating high-speed system equipped with 8 or 10 filling spouts which allow packing speeds of up to 1200 bags/h. THE BENJAMIN® is the compact variant of the ADAMS system and has 1–4 filling spouts. It is ideal for medium–sized capacities in bags from a continuous PE film tube. Compact size and a high degree of flexibility are the prominent features of THE BENJAMIN®.