Maximizing alternative fuel benefits with Expert Optimizer

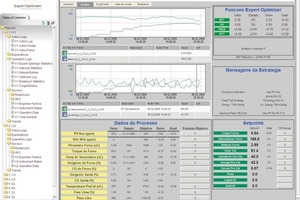

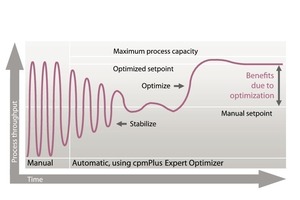

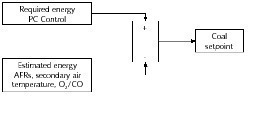

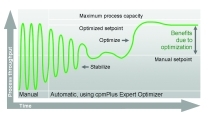

Summary: ABB’s Expert Optimizer was first installed at Votorantim Cimentos’s Itau and Salto plants in 1995. Ageing hardware needed to be replaced in 2008/2009 and at the same time the opportunity to upgrade the optimization solution was taken. Votorantim has the possibility to retain more than 10 years of knowledge acquired from the previous version with these upgrades, plus the opportunity to have access to new technologies like Model Predictive Control (MPC) and Mixed Logical Dynamic (MLD) systems and other new applications developed by ABB. The stabilization of the process results in more consistent clinker quality and this in turn brings benefits to the mills. One of the main benefits that stands out is that both plants now have more stable use and control of the burning of alternative fuels, with less disruption to the process. This has allowed both plants to increase the amount of alternative fuels they use, which in turn is having a positive impact on reducing production costs.

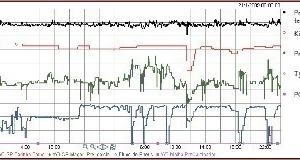

ABB’s Expert Optimizer was first installed at Votorantim Cimentos’s Itau de Minas (Fig. 1) and Salto de Pirapora plants (Fig. 2) in 1995. Ageing hardware needed to be replaced (Fig. 3) and at the same time the opportunity to upgrade the optimization solution was taken. The challenges were to upgrade to the latest version without losing any of the existing plant specific features, and to bring the alternative fuels used in the plants into the strategy and therefore to bring them under better control. The upgrades were completed in 2009.