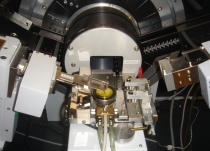

Optimum lubricant supply

GREASE MAX® (Fig.) is a cost-efficient fully automatic, robust and reliable lubricator suitable for a wide variety of applications. It ensures adequate supply for any number of points requiring regular lubrication over a given period of time, doing away with the need for time consuming checks and re-lubrication visits. It functions by means of a chemical reaction that is started by screwing the starter cap into the body. External means of energy are not needed.