Logistics between cement plants and distribution

centers is automated – at least sometimes

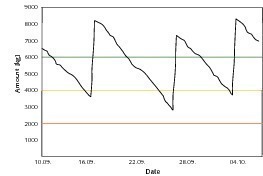

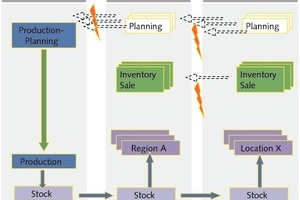

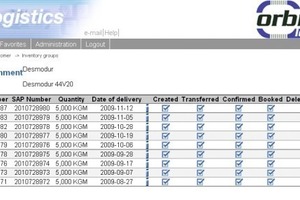

Summary: Cement has to be shipped from the plant to several distribution centers. In these centers the cement powder is mixed with water, sand and gravel, processed to concrete to be distributed with trucks. The demand at every center is quite volatile since it is the point of sale to the end customer. The personnel on site usually do the reordering of new material. To meet the needs of the distribution centers the plant has to be quite flexible and needs a high number of trucks for distribution of new cement powder to the centers. Orbit Logistics creates a Supply Chain Management solution that fits into this environment and helps to save time and money and to reduce transport to protect the environment.

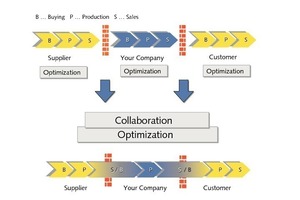

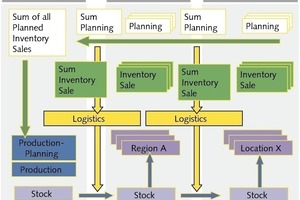

Like no other industry, the cement industry has to cope with high volumes and low prices. This means that logistics is a key to success as it has a great influence on productivity and profit.Poor or even non-optimized logistics can consume the whole profit of a certain product. The flow of information and data has to be managed company-wide. Isolated solutions do not contribute to the desired success. (Fig. 1).

As it is extremely ineffective to transport ready-mixed concrete over long distances, the cement producers usually build up distribution centers. The distribution centers...