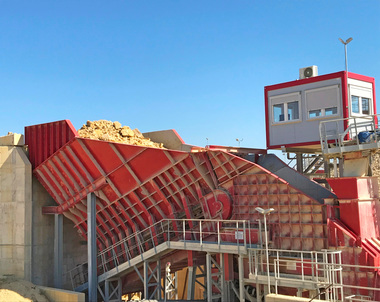

Apron feeder with arched plates for limestone transport

Barely one year after the takeover of the Holcim subsidiary in Venezuela by the state, investments are made to ensure the proper functioning of the system in the South American plant: The responsible managers placed an order with AUMUND Fördertechnik GmbH for one heavy-duty apron feeder (Fig.) with arched plates (2000/150/25+25) of type BPB-S-K and for two spillage conveyors for the limestone transport. This order for AUMUND means the medium term replacement of an apron feeder with arched plates still in operation by the new machine that will be designed for a conveying capacity of 1050 t/h. The heavy-duty apron feeders are preferably installed underneath tipping points and transport uncrushed raw materials. AUMUND apron feeders with arched plates can also be used to discharge moist and sticky materials such as loam, marl, natural gypsum and pozzolana from hoppers. The new apron feeder with arched plates will have a center distance of 18.5 m and will replace an existing third-party product. The spillage conveyors also included in the scope of supply and to be installed underneath will feature a conveying capacity of max. 8.35 t/h and will transport the fines to the collecting chute.