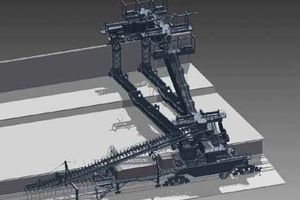

Robust sensor system for automatic operation of a combi-stacker/reclaimer

In the bulk materials industry it is normal for large quantities of material to be stockpiled. For sensitive bulk materials, roofed longitudinal stockyards have come into general use. For reclaiming the material from these stockpiles, rail-mounted portal scraper reclaimers have proven reliable. These machines offer the advantage of requiring little additional space in the hall. If the stacking and reclaiming of the stockpile take place at different times, combi-machines are used.

1 Combi-machine for the

storage of problematic materials

For a project involving the interim storage of granular material with a particle size range of 2-6 mm at ambient temperature, ThyssenKrupp Industrial Solutions GmbH in St. Ingbert supplied a rail-mounted combi-machine (portal scraper reclaimer and belt stacker in one). This machine stacks 2000 t of bulk material per hour and reclaims it as necessary at a rate of 4000 tph via the belt conveyor located behind the machine. The combi-machine is operated automatically, thus reducing the number of persons present in the hazardous atmosphere of the storage hall. The company Endress+Hauser was selected as the supplier of sensor systems, as their devices meet the stringent requirements of the plant owner.

2 Radar measurement

of the distance from the stockpile

Due to the special properties of the bulk material involved, strict safety requirements have to be observed. The dust generation was reduced by appropriate designed of machine and transfer points, as well as particular attention was paid to the monitoring of possible ignition sources. The storage hall is classified as a so-called “Zone 21”, in which “Dust Ex” conditions apply – i.e. danger of dust explosion. For this reason, special precautions have to be taken.

These begin with designing the stacking system for low discharge heights, in order to reduce the dust generation. The combi-machine is therefore equipped with luffing booms. To ensure that the discharge height really follows the level of the stacked bulk material, and that no collisions with the stockpile can occur, filling level sensors of the type FMR250 are installed on the boom. This type of non contact radar sensor has the advantage that the signal intensity is not reduced by conveying and stacking noises, which can easily happen, given by the high conveying rates involved. Moreover, the measuring principle is not sensitive to temperature variations and provides clear signals, despite the dusty atmosphere.

3 Dosed amounts of water for dust reduction

The transfer points are equipped with a moistening system for dust suppression, in order to prevent fine particles of the critical bulk material from spreading freely through the chutes of the combi-machine. The nozzles of these systems produce a water mist that binds the dust and prevent it from swirling into the air. In order not to exceed the precisely defined residual moisture content of the bulk material, the four transfer points are equipped with magnetic-inductive volumeters for recording the water quantities. The advantage of these well-proven measuring devices of the Promag 53P series is that they have no internal inserts that cause a pressure drop in the piping, and that they are not sensitive to the vibrations that can occur in this machine. Moreover, these measuring devices can be easily incorporated into the piping system and are not affected by piping distortions.

4 Detection of blockages

in the transfer chutes

In view of the fact that the combi-machine works automatically without operating personnel, it is necessary to monitor the flow of material. For this reason, the material transfer chutes and the feed idler table are equipped with sensors for detecting bulk material pile-ups. This is a particularly important point, with a stacking capacity of 1000 tph and a reclaiming capacity of 2000 tph per boom. To detect a possible bulk material pile-up, limit switches of the universally applicable Soliphant type M FTM50 were used. These limit switches are easy to install and they are immediately avail-able for use, without needing calibration. For the described application, the Soliphant M switches used were of increased sensitivity, so that a pile-up of material with a low density like dusty bulk material is also reliably detected.

5 Pressure monitoring in the transfer chutes

As a further safety measurement, the material transfer chutes and the feed idler table are also equipped with pressure sensors. These have a small measuring range and are intended for the purpose of monitoring a possible deflagration by means of the associated increase in pressure. For the application at the material stockpile, sensors of the Cerabar PMC51 family, equipped with ceramic measuring cell were selected, as these have very good abrasion and wear resistance characteristics.

Furthermore, the ceramic measuring cells have an overload withstand capability of up to 40 times the nominal pressure. This means that it is not necessary to replace the measuring device after a sudden pressure increase to values exceeding the measuring range. The signal indicating a possible pressure increase in a particular chute is recorded in the control system. If this local pressure increase occurs several times, this indicates a malfunction, and causes the control system to switch the combi-machine to emergency operation and call for operating personnel.

6 Temperature monitoring of rotating components

Combined with deposits of dust in the surrounding area, high surface temperatures of rapidly rotating components can represent a hazard. To prevent such hazardous temperatures from arising, all relevant mechanical components are monitored by contact sensors. These components include all belt pulleys of the integrated tripper carriage, as well as the scraper chain bearings and the drive gearbox. The temperature sensors of the type Omnigrad M TR10 are resistance thermometers. Having vibration-proof mineral insulated measuring elements, they offer the advantage of long service life.

Signal exchange between the sensors takes place via the proven 4-20 mA system. Moreover, as a standard feature, the measuring devices for indication of variable values are equipped with the HART protocol. Taking account of the special demands imposed by the operating environment and the nature of the bulk material, the parts of the measuring system that are in contact with the material are, naturally, made of stainless steel.

7 Conclusions

Automatic operation of complex conveying equipment in a challenging environment calls for the use of a reliable measuring system package that is not affected by the site condition. The described measuring devices have been installed in numerous applications in the bulk material processing industry and have repeatedly proven their effectiveness. They fully meet the safety requirements imposed on measuring systems for automatically operating conveying equipment and satisfy the need for reliable and robust sensor technology.

www.endress.com