REFERENCES

[1] Bentz D., Sato T., De La Varga I., Weiss, WJ (2012): Fine limestone additions to regulate setting in high volume fly ash mixtures.- Cement Concrete

Composites 34 (2012) 11-17 (doi:10.1016/j.cemconcomp.2011.09.004)

Composites 34 (2012) 11-17 (doi:10.1016/j.cemconcomp.2011.09.004)

[2] Boscaro F., Flatt R. (2022): A method for the mix design of low carbon concrete towards industrial production.- Materials Structures 555(2022):

213 (https://doi.org/10.1617/s11527-022-02040-5

213 (https://doi.org/10.1617/s11527-022-02040-5

[3] Bunzel JM., Wilczek, M (2016) Industrielles Recycling von gipshaltigen Abfällen.- in: Thomé-Kozmiensky, KJ. (edit.): Mineralische Nebenprodukte

und Abfälle 3 – Aschen, Schlacken, Stäube und Baurestmassen – ISBN 978-3-944310-28-2

und Abfälle 3 – Aschen, Schlacken, Stäube und Baurestmassen – ISBN 978-3-944310-28-2

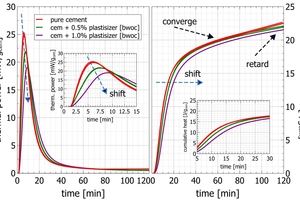

[4] Cheung J., Jeknavorian A., Robert L., Silva D. (2011), Impact of admixtures on the hydration kinetics of Portland cement, Cem. Concr. Res. 41 (2011) 1289–1309, (doi.org/10.1016/j.cemconres. 2011.03.005)

[5] Dengler JE., Grassl H., Bizzozero J. Gädt T. (2024): Analyses of cementitious pore solutions with very high time resolution by coupling cross flow filtration and ICP-OES.- Material Today Communication 39(2024) 109095 ( https://doi.org/10.1016/j.mtcomm.2024.109095)

[6] Enders M. (2003): Quantitative XRD-Analyses in Automated Cement Laboratories: Requirements for the Sample Preparation vol. 56, ZKG International, 2003, pp. 54–62.

[7] Enders M. (2020): The effect of limestone addition and limestone particle size on compressive strength and hydration reactions in semi-industrial Portland limestone cement.- Cement Int 18 (2020/6) 50-62

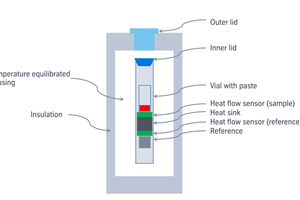

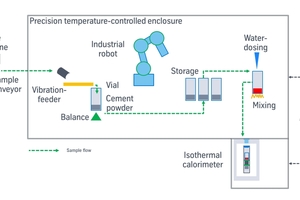

[8] Enders M., Teutenberg R. Sandberg P. (2020): Automated Calorimetry the missing link in quality control.- Int Cem Review 72-74

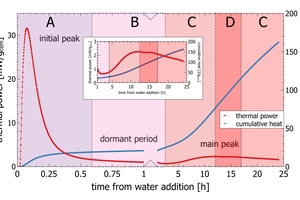

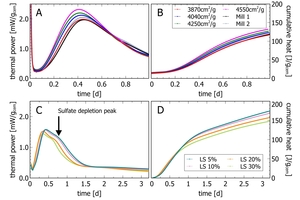

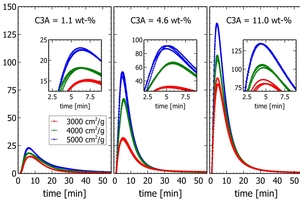

[9] Enders, M. Müller, R., Matschei, Th. (2024): Impact of particle size, clinker mineralogy and sulfate availability on early cement hydration: Observations from isothermal heat-flow calorimetry.- Cem Concr Res 185 (2024) 107613 (https://doi.org/10.1016/j.cemconres.2024.107613)

[10] Frolich L., Wadsö L., Sandberg P. (2014): Using isothermal calorimetry to predict one day mortar strengths, Cem. Concr. Res. 88 (2016) 108–113,

(https://doi.org/10.1016/j. cemconres.2016.06.009).

(https://doi.org/10.1016/j. cemconres.2016.06.009).

[11] GCCA (2023): 2050 Net Zero Roadmap – 1 Year on, Retrieved 30th. https://gccassociatio n.org/concretefuture/wp-content/uploads/2022/10/GCCA-Concrete-Future-Roadmap-Document-AW-2022.pdf, Dec 2023.

[12] Herfort D., Moir GK., Johansen J., Sorrentino F., Bolio Arceo H. (2010): The chemistry of Portland cement clinker, Adv. Cem. Res. 22 (2010) 187–194, (https://doi.org/10.1680/adcr.2010.22.4.187)

[13] ISO (2009): Cement – Test Methods – Determination of Strength. 2009

[14] John E., Lothenbach B. (2023): Cement hydration mechanism through time – a review.- J. Mater Sci 58 (2023): 9805-9833 (doi.org/10.1007/s10853-023-08651-9)

[15] Lerch, W. (1946): The Influence of Gypsum on the Hydration and Properties of Portland Cement Pastes, ASTM Bulletin No 12, ASTM, 1946

[16] Lothenbach B., Damidot D., Matschei Th., Marchand J. (2010): Thermodynamic Modelling: state of knowledge and challenges.- Adv. Cem. Res. 22 (2019: 211-223 (doi: 10.1689/adcr.2010.22.4.211)

[17] Matschei et al (2024): 1st RILEM Int Conference on Carbonation for Cement and Concrete, Aachen 16/17th April 2024

[18] Matschei Th., Glasser FP. (2010): Temperature dependence, 0-40°C, of the mineralogy of Portland cement paste in the presence of calcium carbonate.- Cem Concr. Res 40 (2010) 763-777 (https://doi.org/10.1016/j.cemconres.2009.11.010)

[19] Matschei Th., Kruspan, P., Sandberg, P., Wadsö L (2019), Sulphate optimization of binders containing Portland cement clinker using isothermal calorimetry, in: Proceedings 15th ICCC, Prague, September 16–20, 2019.

[20] Pourchet S., Regnaud L., Perez JP., Nonat A. (2009): Early hydration on the presence of different kinds of calcium sulfate.- Cem Concr Res 39 (2009):

989 - 996 et al (2009) (doi:10.1016/j.cemconres.2009.07.019)

989 - 996 et al (2009) (doi:10.1016/j.cemconres.2009.07.019)

[21] Pustovcar E., Dèspinose, JP., Palacios M., Andreev A., Mishra R., Flatt R. (2016): Impact of Aluminates on Silicate hydration.- in Galvez et al (2016):

Second Int. Conference on Concrete Sustainability. Barcelona: Int. Center Numerical Methods Engineering (ISBN 978-84-945077-7-9)

Second Int. Conference on Concrete Sustainability. Barcelona: Int. Center Numerical Methods Engineering (ISBN 978-84-945077-7-9)

[22] Redondo-Soto C., Gastaldi D., Irico S., Canonico F., Aranda MAG: (2022): Belite clinkers with increasing aluminium content: Effect of calcium aluminates on calcium silicate hydration, Cem Concr Res 162 (2022), (doi.org/10.1016/j.cemconres.2022.107015)

[23] Sandberg P., Teutenberg R., Enders M. (2020): When dreams come true.- World Cement (Nov. 2020) 59-62

[24] Scherrer GW., Bellmann F. (2018) Kinetic analyses of CSH growth on calcite.- Cem Concr Res 103 (2018) 226 – 235 (https://doi.org/10.1016/j.cemconres.2016.07.017)

[25] Scrivener KL., Nonat A. (2011): Hydration of cementitious materials, present and future.- Cem Concr. Res 41 (2011) 651 – 665 (https://doi.org/10.1016/j.cemconres.2011.03.026)

[26] Sharp JK., Gartner EM., MacPhee DE (2010): Novel cement systems (sustainability). Session 2 of the Fred Glasser Cement Science Symposium.-

Adv Cem Res 22 (2010): 195-202 (doi: 10.1680/adcr.2010.22.4.195)

Adv Cem Res 22 (2010): 195-202 (doi: 10.1680/adcr.2010.22.4.195)

[27] Sugzdaite A., Wadsö L., Enders M. (2024): Fast track: the first hour of cement hydration in isothermal calorimetry.- IEEE IAS/PCA Cement Industry

Conference in Denver, 28th April 2024 – May 2rd 2024

Conference in Denver, 28th April 2024 – May 2rd 2024

[28] Tanaka N., Stigson B. (2009): Cement Technology Roadmap, The World Council for Sustainable Development, 2009 (978-3-940388-47-6).

[29] Vollpracht A., Lothenbach B., Snellings R. Haufe J. (2016): The pore solution of blended cements: a review.- Materials Structures 49 (2016) 3341-3367 (Doi 10.1617/s11527-015-0724-1)

[30] Wadsö L., Winnefeld F., Riding K., Sandberg P. (2016, Calorimetry, in: K. Scrivener, et al.(Eds.), A Practical Guide to Microstructural Analyses of

Cementitious Materials, CRC Press, Boca Raton, 2016, pp. 37–74 (ISBN 13: 978-1-4987-3865-1).

Cementitious Materials, CRC Press, Boca Raton, 2016, pp. 37–74 (ISBN 13: 978-1-4987-3865-1).