REFERENCES

[1] Li ZY, Liu JS. Research on the development and countermeasures of green building under the goal of “carbon peak and carbon neutrality” [J]. Southwest Finance, 2021 (10): 55-66.

[2] Zeng R, Liao RH, Xiao LF. Research progress on environmental sustainability in cement production [J]. Development Guide to Building Materials, 2022, 20 (4): 1-8.

[3] Kamon M, Katsumi T, Sano Y. MSW fly ash stabilized with coal ash for geotechnical application [J]. Journal of Hazardous Materials, 2000, 76 (2-3): 265-283.

[4] Wang XY. Analysis of hydration and strength optimization of cement-fly ash-limestone ternary blended concrete [J]. Construction and Building Materials, 2018, 166: 130-140.

[5] Ojha A, Aggarwal P. Durability performance of low calcium Flyash-Based geopolymer concrete [J]. Structures, 2023, 54: 956-963.

[6] Shaikh FUA, Dobson J. Effect of fly ash on compressive strength and chloride binding of seawater-mixed mortars [J]. Journal of Sustainable Cement-based Materials, 2019, 8 (5): 275-289.

[7] Hou PK, Kawashima S, Wang KJ, et al. Effects of colloidal nanosilica on rheological and mechanical properties of fly ash–cement mortar [J]. Cement and Concrete Composites, 2013, 35 (1): 12–22.

[8] Liu M, Tan HB, He XY. Effects of nano-SiO2 on early strength and microstructure of steam-cured high volume fly ash cement system [J]. Construction and Building Materials, 2019, 194: 350-359.

[9] Zou FB, Tan HB, He XY, et al. Effect of triisopropanolamine on compressive strength and hydration of steaming-cured cement-fly ash paste [J]. Construction and Building Materials, 2018, 192: 836-845.

[10] Park B, Choi YC, et al. Effects of fineness and chemical activators of the hydration and physical properties of high-volume fly-ash cement pastes [J]. Journal of Building Engineering, 2022, 51: 104274.

[11] Alahrache S, Winnefeld F, Champenois JB, et al. Chemical activation of hybrid binders based on siliceous fly ash and Portland cement [J]. Cement & Concrete Composites, 2016, 66: 10-23.

[12] Zhang F, Bai Y, Cai YB, et al. Research status of low temperature early strength agents for concrete [J]. Materials Review, 2017, 31 (21): 106-113.

[13] Wu P, Lu XJ, Liang ZQ, et al. The mechanism and application of concrete hardening accelerator [J]. Metal Mine, 2014, (12): 20-25.

[14] Jiang MF, Lv XJ. Research and application progresses of concrete early strength agent [J]. Bulletin of Chinese Ceramic Society, 2014, 33 (10): 2527-2533.

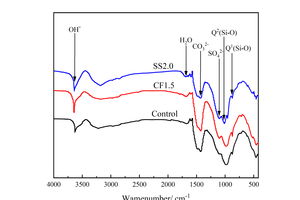

[15] Criado M, Jiménez AF, Palomo A. Effect of sodium sulfate on the alkali activation of fly ash [J]. Cement and Concrete Composites, 2010, 32 (8): 589-594.

[16] Zou FB, Hu CL, Wang FZ, et al. Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C-S-H seeds towards a greener binder [J]. Journal of Cleaner Production, 2020, 244: 118566.

[17] Lv QF, Wang ZS, Gu LY, et al. Effect of sodium sulfate on strength and microstructure of alkali-activated fly ash based geopolymer [J]. Journal of Central South University, 2020, 27 (6): 1691-1702.

[18] GB/T 17671-2021. Method of testing cements–Determination of strength [S]. Beijing, China.

[19] Zhang F, Bai Y, Cai YB. Effect of calcium formate on early hydration of cement at 5 °C [J]. Materials Reports, 2021, 35 (10): 10055-10061+10087.

[20] Heikal M. Effect of calcium formate as an accelerator on the physicochemical and mechanical properties of pozzolanic cement pastes [J]. Cement and Concrete Research, 2004, 34 (6): 1051-1056.

[21] Xu X. Effect of admixture on performance when droping only or mixed with the other admixture under steam curing [D]. Hefei: Anhui Jianzhu University, 2016.

[22] Sun DS, Xu W, Wang AG, et al. Effect of calcium formate on the compressive strength, hydration and pore structure of cement pastes [J]: Journal of Anhui Institute of Architecture & Industry (Natural Science), 2013, 21 (6): 54-58.

[23] Ma BG, Zhu YC, Hu D, et al. Influence of calcium formate on sulphoaluminate cement hydration and harden process at early age [J]. Journal of Functional Materials, 2013, 44(12): 1763-1767.

[24] Pang CM, Tang ZY, Yang ZY, et al. Early strengthening agent in cementitious composites and its function mechanism: a review [J]. 2023, 37 (9): 80-90.

[25] Zhang BL, Tan HB, Shen WG, et al. Nano-silica and silica fume modified cement mortar used as surface protection material to enhance the impermeability [J]. Cement and Concrete Composites, 2018, 92: 7-17.

[26] Mei JP, Tan HB, Li HN, et al. Effect of sodium sulfate and nano-SiO2 on hydration and microstructure of cementitious materials containing high volume fly ash under steam curing [J]. Construction and Building Materials, 2018, 163: 812-825.

[27] Mei JP, Ma BG, Tan HB, et al. Influence of steam curing and nano silica on hydration and microstructure characteristics of high volume fly ash cement system [J]. Construction and Building Materials, 2018, 171: 83-95.

[28] Li X. Formation mechanism of hydration microstructure of cement-fly ash based on nano-thermal coupling effect [J]. Wuhan: Wuhan University of Technology, 2017.