Simulation of limestone calcination in normal shaft kilns – mathematical model

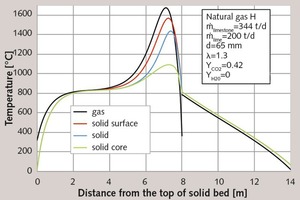

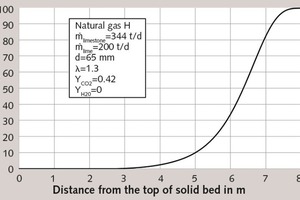

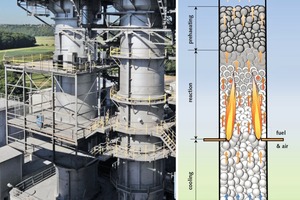

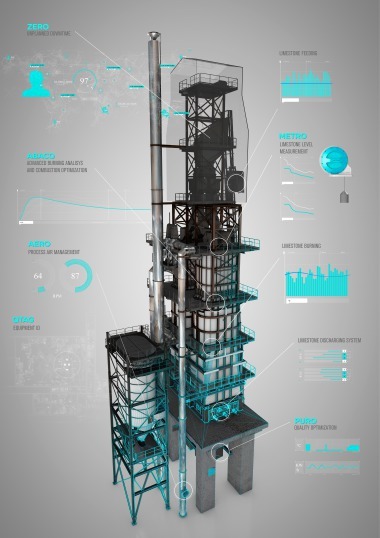

The process of calcination in normal shaft kilns can be described and simulated by means of a mathematical model in which the operating conditions, material properties and kiln geometry serve as variables. The results can be used for purposes of process optimization, kiln design and personnel training.

1 Introduction

Lime burning, i.e., the calcination of limestone, is a very complex process, because it involves numerous significant parameters – including:

the operating conditions (throughput, fuel quantity, combustion air quantity, fuel type and composition, ambient temperature, air speed),

the kiln geometry (diameter, height of solid bed, length of cooling zone, thickness of wall layers) and

the characteristics of the stone (average size, particle size distribution, calcite component, magnesite component, thermal conductivity, reactivity, moisture content)

Due to the large number of parameters,...