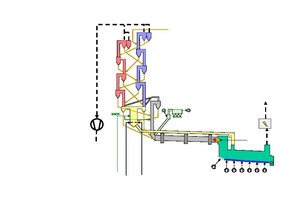

In-line calciner conversion

at LafargeHolcim Mannersdorf

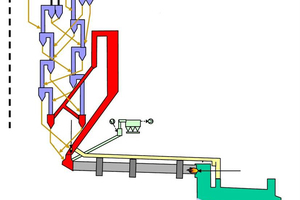

With the current trend of maximizing the substitution rates of alternative fuels while emission regulations are becoming more restricted, the cement industry is facing various challenges. While for in-line calciner systems the use of solid alternative fuels is well proven, separate-line calciners are in many cases limited to a great extent as regards the use of this fuel. LafargeHolcim in Mannersdorf/Austria has set a goal for maximizing solid alternative fuel rates with simultaneous reduction of CO and NOX emissions. To reach this target a conversion from the existing separate-line calciner to an in-line calciner for the kiln line in Mannersdorf has been done, considering the restrictions of the existing system, aiming at 100 % solid alternative fuel utilization in the calciner and reaching lower emission values. In addition, the increase of preheater efficiency was also addressed in this project. A TEC Production and services acted for this as supplier for technology and engineering as well as for equipment supply and the necessary site works for installation on a turn-key basis.

1 Introduction

Due to the high demand of thermal energy for clinker production, fuel economics as well as emissions are a central topic for efficient and sustainable clinker production [1].

Using alternative fuels offers kiln operators the possibility to reduce emissions as well as to be more competitive on the market due to the cost savings regarding fuel costs of fossil fuels [2].

The utilization of alternative fuels, however, comes with several challenges for the process with disadvantages such as insufficient burn-out which might lead to increased emission levels and impact on the production...