Impact of clinker coolers

on downstream equipment

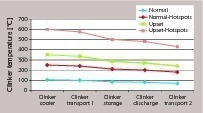

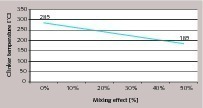

Clinker coolers in today’s cement pyroprocessing lines are considered to be very reliable even under kiln upset conditions. But what is the interaction of the cooler with the upstream pyroprocessing under extreme conditions and how is the downstream equipment affected? In the following article the process will be analyzed and questions answered.

1 Introduction

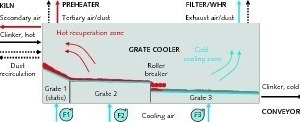

Modern clinker coolers require 1.7 to 2.0 Nm³/kgcli. of fresh air to cool clinker with temperatures of more than 1400 °C from the rotary kiln to outlet temperatures below 100 °C. Such clinker coolers recuperate most of the thermal energy in the clinker to provide secondary air for the burning process and tertiary air for pre-calcination achieving thermal efficiencies of about 75 % and more. Clinker coolers are also required to buffer kiln fluctuations and have no or only a minor effect on the upstream pyroprocessing system which comprises pre-heater, pre-calciner, kiln and fuel...

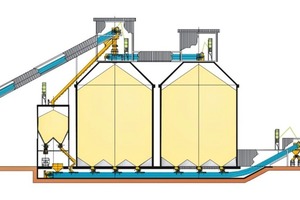

![12 Dimensioning of clinker conveyors [4]](https://www.zkg.de/imgs/tok_40d0ccafe1ff2ebe77f655857d46c071/w203_h121_x101_y60_101546681_6a5eb632a5.jpg)