KHD Humboldt Wedag –

Focussing on the plant service business

KHD Humboldt Wedag can trace its origins back to 1856. One of the leading global cement plant and equipment suppliers, KHD provides services such as design and engineering, project management and supply, as well as supervision of erection and commissioning of cement plants and equipment. The company has its headquarters in Cologne/Germany and operates functionally worldwide via four Customer Service Centres (CSC) in India; the Americas; Europe, the Middle East and Africa (EMEA) and CIS. KHD also has operations in Asia Pacific, China and Australia (Fig. 1). On the occasion of the AUCBM conference in Ras Al Khaimah/UAE, ZKG INTERNATIONAL spoke with Ralf Slomski, Managing Director, Humboldt Wedag GmbH and Head of KHD operations in EMEA, about the developments, current trends and future perspectives for KHD.

Ralf Slomski: If you look at the recent statistics, the Middle East expects cement volume to increase by 8 % in 2011 (Fig. 2). This is a growth rate which is only comparable to that of the BRIC countries! Traditionally, KHD has had a strong presence in this region and we expect to gain from this growth potential. Therefore, it was very important for us to be present at the AUCBM. Since 2009 the market for Europe and the Middle East is very flat. Opportunities are mainly driven by efficiency improvement, reduction of power consumption, fulfilment of new environmental standards and green cement. Especially the GCC region faced a huge over-capacity which has to be resolved by export. Therefore major CAPEX opportunities (with some small exceptions such as the remaining licences in Saudi Arabia) are in the field of export terminals for clinker and cement. There is still a good market potential in countries like Yemen, Syria and Turkey as well in the whole of North Africa.

In sub-Saharan Africa however, after having passed the financial crisis, markets are clearly picking up. Customers are more strategic than in the past and are asking for fulfilment of their long term requirements. They are building on flexible and cost effective platforms. TCO (Total Cost of Ownership) is an issue here and this is exactly where KHD has its strength since we can easily demonstrate that our solutions are competitive in terms of investment cost and even more when comparing TCO. It is a good time to invest in the markets in terms of meeting the specific needs of the customer and cooperating in partnership with them in developing the customized solutions they seek.

Ralf Slomski: In Europe efficiency and emissions are of course huge issues. In the Middle East and also in Africa customers are becoming more and more aware of these issues and also place a strong focus on quality. We are seeing an increased interest in our COMFLEX grinding technology, which offers the same output and quality as a vertical mill at lower energy costs. Low energy consumption (fuel, electricity), low polluting technologies, alternative fuels, smaller and more efficient machines and departments and also solutions to gain more from existing installations with less (resources, energy, specific operation and investment costs) as a proactive measure are further technological trends.

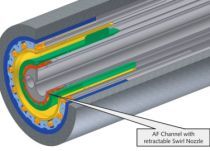

Ralf Slomski: KHD offers end-to-end project management for complete cement plants, individual equipment packages and the full range of plant services. In 2011 we will focus on the plant service business. KHD’s audit team conducts onsite audits for process functions, mechanical equipment, automation and even for environmental matters. Here we can usually show a customer how he can increase his efficiency in the respected area and thus improve its profit. One example: In order to increase the service life of the refractory of a PYRO-JET® burner, KHD has developed a special cooling tube with fins (Fig. 3). This increases the heat exchange between cooling air and refractory which helps to avoid downtime. Furthermore, the tube itself has higher resist-ance against heat and dust in case of refractory failure and therefore gives extra protection for the burner tip. Often there are only small factors in operation that can mean big savings for the customer. We are expanding our service base and through four designated service segments, we are offering spare parts (cost competitive, fast tender process and delivery time), and service with and without tools (SWIT, SWOT) as well as developing the O&M service business segment.

Ralf Slomski: We are just finishing Al Qatrana in Jordan, a complete line with a capacity of 5000 t/d. In addition, we are working on some very potential opportunities in Turkey. Here in the region we have recently been awarded the Güris¸ project in Syria for a new pyroprocessing system with a capacity designed for 4000 t/d clinker. The Turkish owner Güris¸ already operates two cement grinding and packing plants in Syria and this contract is part of the new ongoing investment in a cement factory, which will be installed in Al Raqqah, The new kiln line will incorporate state-of-the-art technology from KHD Humboldt Wedag including preheater/calciner system, rotary kiln and cooler. Delivery is scheduled for the second half of 2011. Furthermore we have significant opportunities all over Africa that we are sure to win with competitive offers.

Ralf Slomski: The strategic partnership with CATIC combines the best of both worlds, offering customers a new option for EPC projects. We are very optimistic about our chances that our new partner founded in 1979 with over 25 000 employees, will open up the world’s largest market for our products in China. CATIC also has EPC experience outside of China and has built number of cement plants. CATIC is ISO 9001 certified and is among the top 10 conglomerates in China. We are convinced that this partnership will benefit both companies!